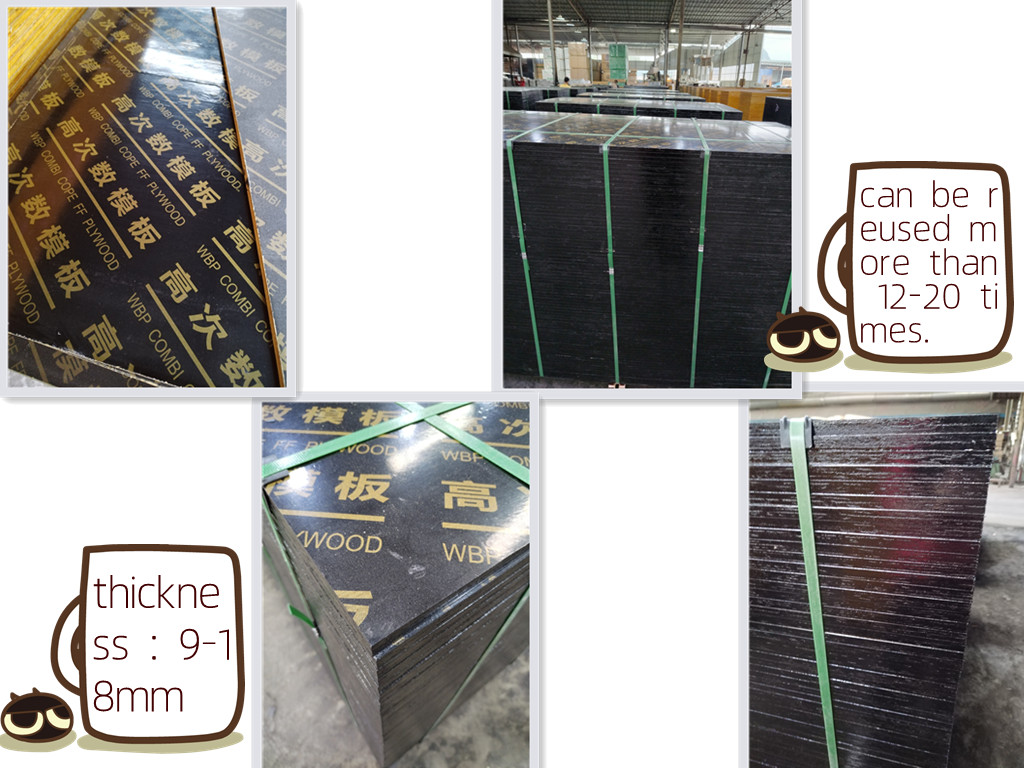

Today's special recommendation: film faced plywood pine board

Eucalyptus core and pine panel

Plywood Factory Outlet

Perfect quality and high performance

Production process:

1. Select high-quality eucalyptus first-class core board

2. Over glue

3. Typesetting

4. Cold pressing to shape

5. Attach the phenolic adhesive film

6. Hot pressing above 160°, temperature at Moderate 120-128 degrees

7. Check the board (whether there is an explosion board. Leakage)

8. Saw edge

9. Edge sealing (brush a layer of putty powder)

10. Painting

11. Packaging

Process features:

1. Use good pine and eucalyptus whole core boards, and there are no holes in the middle of the blank boards after sawing;

2. The surface coating of the board/plywood is phenolic resin glue with strong waterproof performance, and the core board adopts melamine glue (single layer glue can reach 0.45KG)

3. First cold-pressed and then hot-pressed, and pressed twice, the structure of board/plywood is stable.

Advantages of this product:

1. Select high-quality eucalyptus veneer, first-class panels, good materials can make good products

2. The amount of glue is sufficient, and each board is 5 taels more glue than normal boards

3. Strict management system to ensure that the discharged board surface is flat and the sawing density is good.

4. The pressure is high.

5. The product is not deformed or warped, the thickness is uniform, and the board surface is smooth.

6. The glue is made of melamine according to the national standard of 13%, and the product is resistant to sunlight, water and moisture.

7. Wear-resistant, heat-resistant, durable, no degumming, no peeling, can be used repeatedly for more than 12 times.

8. Good toughness, high strength and high usage times

Post time: May-04-2022