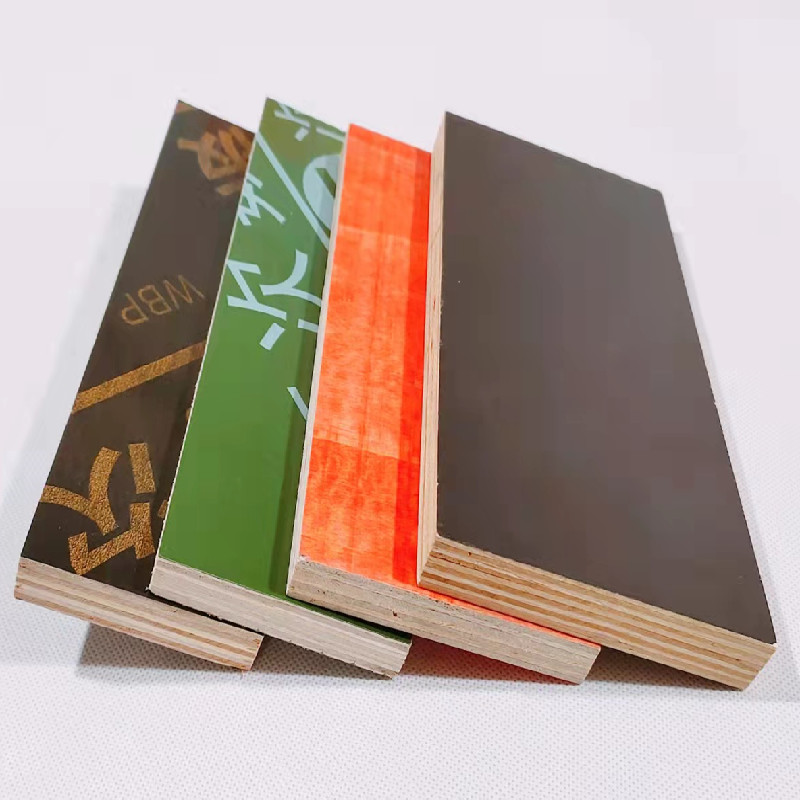

In the last week, we updated some product information. Our main products: phenolic board, film faced plywood, the description of the product is more perfect.

Scope of application: used to support concrete pouring construction, mainly used in bridge construction, high-rise buildings and other construction industries.

Process features:

1. Use good pine and eucalyptus whole core boards, and there are no holes in the middle of the blank boards after sawing;

2. The surface coating of the board/plywood is phenolic resin glue with strong waterproof performance, and the core board adopts melamine glue (single layer glue can reach 0.45KG)

3. First cold-pressed and then hot-pressed, and pressed twice, the structure of board/plywood is stable.

8 advantages of our products:

1. Select high-quality eucalyptus veneer, first-class panel, good materials can make good products

2. The amount of glue is sufficient, and each board is 5 taels more glue than normal boards

3. Strict management system to ensure that the discharged board surface is flat and the sawing density is good.

4. The pressure is high.

5. The product is not deformed or warped, the thickness is uniform, and the board surface is smooth.

6. The glue is made of melamine according to the national standard of 13%, and the product is resistant to sunlight, water and moisture.

7. Wear-resistant, heat-resistant, durable, no degumming, no peeling, can be used repeatedly for more than 16 times.

8. Good toughness, high strength and high usage times.

Some common problems and how to prevent them:

1. Cracks: Reasons: panel cracks, rubber board cracks. Preventive measures: When screening (when selecting boards), pay attention to pick them out, screen non-destructive plastic boards, and arrange them neatly.

2. Overlap: Reason: plastic board, dry board, the filling is too large (the interval is too large (too small). Preventive measures: fill the hole according to a certain size, and cannot exceed the original hole.

3. White leakage: Reason: It is not uniform enough when the red oil is passed once or twice. Preventive measures: During the inspection, manually add red oil.

4. Explosion board: Reason: wet board (plastic board) is not dry enough. Precautions: Inspect wood core boards when shipping.

5. The board surface is rough: Reason: fill the hole, the wood core board knife tail is thinner. Preventive measures: try to choose a flat wood core board.

Post time: Apr-18-2022