The quality of the wooden formwork depends on the veneer.There are uniform steps in the industry: see, listen, and step on,which are simple and easy. Heibao Wood needs to add something: smell, and to look at the leftover material . The following content has detailed methods, I hope it can help you!

First: look

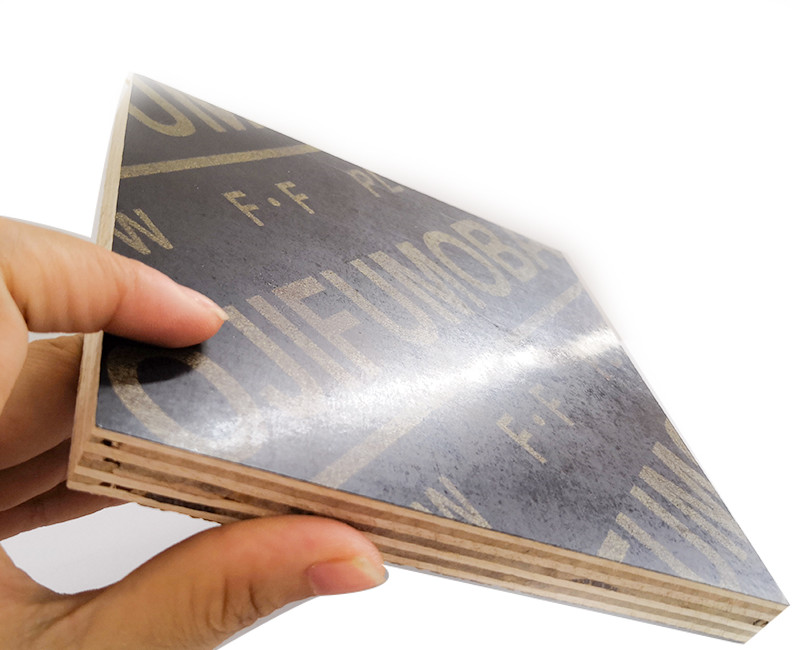

1. Whether the surface of the wooden template is smooth and flat. Smooth and flat, making it easy to demold during use, the surface of the concrete is smooth, and it also indicates the amount of glue on the surface (the more the amount of glue, the brighter and flatter the surface); whether the assembly is uniform during the production process (unbalanced, pressed out of the board) It is not flat), whether the production equipment is good (the better the equipment, the flatter and brighter the surface is).

2. Board edge: Whether the thickness of the board edge is the same. If the board-to-board tolerance is large, the concrete surface will not be on the same horizontal line. Second, whether the edge of the board is handled well, the cavities are filled and the painting is even, this is related to the problem of waterproofing during the use of the wooden formwork, and it also reflects the level of the enterprise's craftsmanship.

Second: listen

This is relatively simple. It only takes two people to work together, each holding both ends of the wooden formwork, "shake" the whole board with cross force, and then listen to the sound of the wooden formwork. If the sound is like a "boom" sound made by the shaking of a steel sheet, it means that the heat pressure of the board is better, the intensity is greater, and the louder and thicker the sound, the better the quality of the product. On the contrary, if the sound is hoarse or "hissing" ,the sound as if there is some tear, indicates that the strength is not enough, the structure is not good, either the glue is not good, or the hot pressing process has a problem.

Third: Step on

The normal good wooden formwork is 8mm thick, hung in the middle, and the distance between the two supporting parts is about 1m. It can effectively carry an 80kg adult who can jump and bounce on the suspended part without breaking. Otherwise its quality is worth considering.

These three tricks are simple and easy to implement, and can be compared to reflect the quality of the product. A more professional testing method is "poaching", which is sent to the Quality Supervision Bureau for all inspections. Look at the bonding strength of the product after being boiled for a certain period of time, air-dried and frozen.The Inspection certificate will be issued by China Import and Export Commodity Inspection Bureau or by any of its branches.

These three tricks are still simple and practical. But if you go to the factory for field inspections, there are more professional and practical skills to share with you.

Stay tuned to be continued

Post time: Aug-30-2021