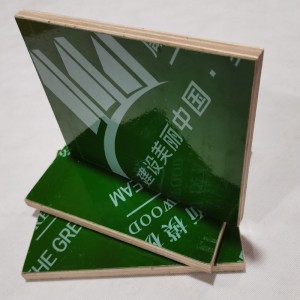

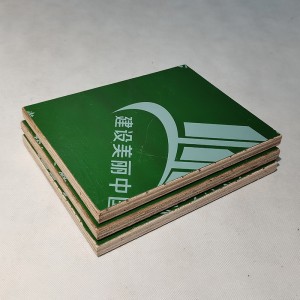

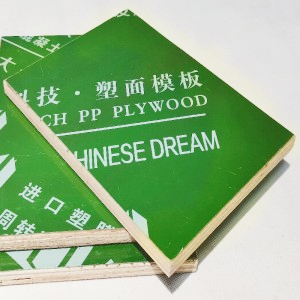

Plastic Plywood for Construction

Product Details

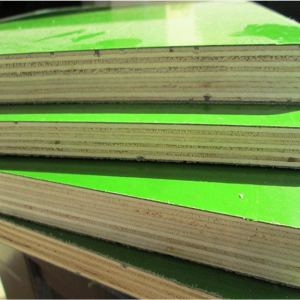

During production, each plywoods will use special high-quality and sufficient glue, and equipped with master craftsmen to adjust the glue; Using professional machinery to embed the tempered film on the plywood, and the edge is 0.05mm thick double-sided glue is applied, and the inner plywood core is closely connected after hot pressing. The physical and mechanical properties are much higher than traditional laminated plywood, such as high mechanical cohesion/high strength, high temperature resistance/corrosion resistance, high abrasion resistance/excellent chemical resistance, waterproof and moisture-proof, recyclable and reusable (more than 25 times).

During the production process, employees are required to typeset rationally and scientifically to avoid excessive gaps between the boards to increase the bending strength and the number of turns to make the concrete solidify smoother and increase the number of repeated uses.

Due to the unique performance and technology of the green plastic faced surface construction plywood, its application range is also relatively wide. It is usually applicable to various infrastructure projects such as bridges, tunnels, dams, high-speed highways, high-rise buildings, etc., such as in high-rise buildings, the green platsic plywood can be used to complete a 30 floors building, which can greatly save costs and working hours.

Advantage:

1. Select high-quality eucalyptus veneer, first-class panel, good materials can make good products

2. The amount of glue is sufficient, and each board is 5 taels more glue than normal boards

3. Strict management system to ensure that the discharged board surface is flat and the sawing density is good.

4. The pressure is high.

5. The product is not deformed or warped, the thickness is uniform, and the board surface is smooth.

6. The glue is made of melamine according to the national standard of 13%, and the product is resistant to sunlight, water and moisture.

7. Wear-resistant, heat-resistant, durable, no degumming, no peeling, can be used repeatedly for more than 16 times.

8. Good toughness, high strength and high usage times.

Company

Our Xinbailin trading company mainly acts as an agent for the building plywood directly sold by Monster wood factory. Our plywood are used for house construction, bridge beams, road construction, big concrete projects, etc.

Our products are exported to Japan, UK, Vietnam,Thailand,etc.

There are more than 2,000 construction purchasers in cooperation with Monster Wood industry. At present, the company is striving to expand its scale, focusing on brand development, and creating a good cooperation environment.

Guaranteed Quality

1.Certification: CE, FSC, ISO, etc.

2. It is made of materials with a thickness of 1.0-2.2mm, which is 30%-50% more durable than the plywood on the market.

3. The core board is made of environmentally friendly materials, uniform material, and the plywood does not bonding gap or warpage.

Parameter

| Item | Value | Item | Value |

| Place of Origin | Guangxi, China | Main Material: | pine,eucalyptus |

| Brand Name | Montser | Core: | pine,eucalyptus,or requested by clients |

| Model Number | Plastic Faced Plywood | Face/Back: | Green Plastic/Custom(can print logo) |

| Grade | FIRST-CLASS | Glue: | MR, melamine, WBP, phenolic |

| Size | 1830*915mm/1220*2440mm | Moisture Content: | 5%-14% |

| Thickness | 11mm-18mm or as required | Density | 610-660 kg/cbm |

| Number of Plies | 8-11 layers | Certificate | FSC or as required |

| Thickness Tolerance | +/-0.2mm | Cycle life: | Turnover more than 25 times |

| Formaldehyde Release | E2≤5.0mg/L | Packing | Standard Export Pallet Packing |

| Usage | Outdoor,construction,bridge,etc | MOQ: | 1*20GP. Less is acceptable |

| Delivery Time | Within 15 days after order confirmed | Payment Terms: | T/T, L/C |

FQA

Q: What are your advantages?

A: 1) Our factories have more than 20 years experiences of producing film faced plywood, laminates, shuttering plywood,melamine plywood,particle board,wood veneer,MDF board,etc.

2) Our products with high-quality raw materials and quality assurance, we are factory-directly sale.

3) We can produce 20000 CBM per month, so your order will be delivered in a short time.

Q: Could you print the company name and logo on the plywood or packages?

A: Yes, we can print your own logo on plywood and packages.

Q: Why we choose Film Faced Plywood?

A: Film Faced Plywood is better than iron mould and can satisfy the requirements of constructing mould, the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing.

Q: What is the lowest priced film faced plywood?

A: Finger joint core plywood is cheapest in price. Its core is made from recycled plywood so it has low price. Finger joint core plywood can only be used two times in formwork. The difference is that our products are made of high-quality eucalyptus/pine cores, which can increase the reused times by more than 10 times.

Q: Why choose eucalyptus/pine for the material?

A: Eucalyptus wood is denser, harder, and flexible. Pine wood has good stability and ability to withstand lateral pressure.