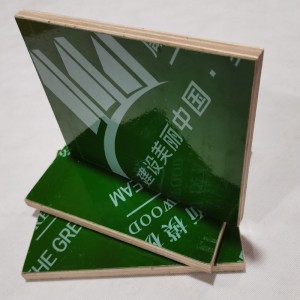

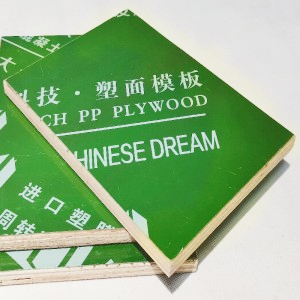

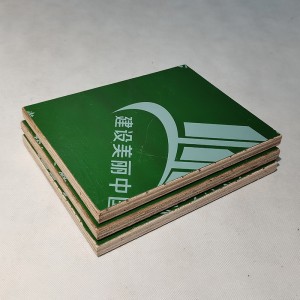

Durable Green Plastic Faced Laminated Plywood

Product Description

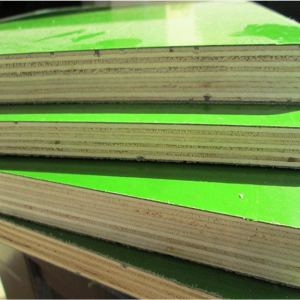

The factory has excellent technology to produce durable plastic faced plywood. The inside of the formwork is made of high-quality wood, and the outside is made of waterproof and wear-resistant plastic surface. Even if it is boiled for 24 hours, The board's adhesive will not failure. The plastic faced plywood has the effect characteristics of a construction plywood, high strength, sturdiness and durability, and easy to disassemble, which makes the building shape beautiful and has a wide range of applications. General buildings and bridges can use our green laminated plywood. It is worth mentioning that the green laminated plywood is light in weight, and it’s convenient to transport to multiple construction sites. And more durable than other construction plywood,compare with the other construction plywood, it can be recycled up to 25 times. Finally,we provide customers with customized specifications and thickness services.

Use Technical Guidance

1. Store goods with plastic-coated plywood to avoid rain, and at least three wooden pallets should be used to level the bottom to avoid deformation of the plastic-surface plywood

2. When unloading the mold, two workers cooperate and pry the two ends of the board at the same time, and try to let the whole board fall horizontally.

3.Use 120 tooth alloy steel saw blade when sawing the board.

4.If there are cracks on the edges, please saw them off during the cleaning process. The edge of the saw board should be brushed twice with ordinary paint.

5.Use wet rags or water to clean the surface of the board every two demolding to ensure that the surface of the plastic film faced plywood is smooth and the molding is bright.

6. Vibration must be sufficient.

Company

Our Xinbailin trading company mainly acts as an agent for the building plywood directly sold by Monster wood factory. Our plywood are used for house construction, bridge beams, road construction, big concrete projects, etc.

Our products are exported to Japan, UK, Vietnam,Thailand,etc.

There are more than 2,000 construction purchasers in cooperation with Monster Wood industry. At present, the company is striving to expand its scale, focusing on brand development, and creating a good cooperation environment.

Guaranteed Quality

1.Certification: CE, FSC, ISO, etc.

2. It is made of materials with a thickness of 1.0-2.2mm, which is 30%-50% more durable than the plywood on the market.

3. The core board is made of environmentally friendly materials, uniform material, and the plywood does not bonding gap or warpage.

Parameter

| Place of Origin | Guangxi, China | Main Material | Pine, eucalyptus |

| Brand Name | Monster | Core | Pine, eucalyptus or requested by clients |

| Grade/Certificate | First-Class/FSC or requested | Face/back | Green plastic/Custom(can print logo) |

| Size | 1220*2440mm/1830*915mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 11-18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 8-11layers | Density | 620-680 kg/cbm |

| Thickness Tolerance | +/-0.3mm | Cycle life | Recycle more than 25-30 times |

| Usage | Outdoor, construction, big concrete projects ,bridge, etc. | Packing | Standard Export Pallet Packing |

| Delivery Time | Within 15 days after order confirmed | Payment Terms | T/T, L/C |

FQA

Q: What are your advantages?

A: 1) Our factories have more than 20 years experiences of producing film faced plywood, laminates, shuttering plywood,melamine plywood,particle board,wood veneer,MDF board,etc.

2) Our products with high-quality raw materials and quality assurance, we are factory-directly sale.

3) We can produce 20000 CBM per month, so your order will be delivered in a short time.

Q: Could you print the company name and logo on the plywood or packages?

A: Yes, we can print your own logo on plywood and packages.

Q: Why we choose Film Faced Plywood?

A: Film Faced Plywood is better than iron mould and can satisfy the requirements of constructing mould, the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing.

Q: What is the lowest priced film faced plywood?

A: Finger joint core plywood is cheapest in price. Its core is made from recycled plywood so it has low price. Finger joint core plywood can only be used two times in formwork. The difference is that our products are made of high-quality eucalyptus/pine cores, which can increase the reused times by more than 10 times.

Q: Why choose eucalyptus/pine for the material?

A: Eucalyptus wood is denser, harder, and flexible. Pine wood has good stability and ability to withstand lateral pressure.

Production Flow

1.Raw Material → 2.Logs Cutting → 3.Dried

4.Glue on each veneer → 5.Plate Arrangement → 6.Cold Pressing

7.Waterproof Glue/Laminating →8.Hot Pressing

9.Cutting Edge → 10.Spray Paint →11.Package