China Wholesale Wood Core Plywood Factories - Melamine Faced Concrete Formwork Plywood – Xinbailin

China Wholesale Wood Core Plywood Factories - Melamine Faced Concrete Formwork Plywood – Xinbailin Detail:

Product Description

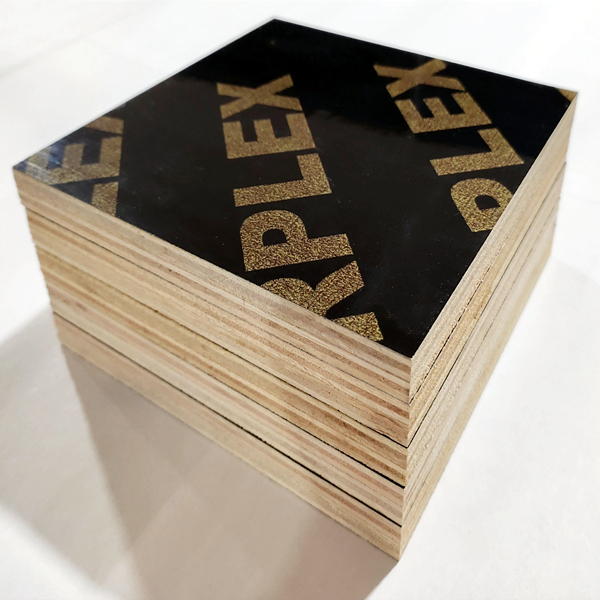

There are no gaps on the side to prevent rainwater from entering. It has good waterproof performance and the surface is not easy to wrinkle. Therefore, it is used more frequently than ordinary laminated panels. It can be used in areas with harsh weather and is not easy to crack and not deform.

The black film faced laminates are mainly 1830mm*915mm and 1220mm*2440mm, which can be produced according to the thickness requirements of 8-11 layers of customers. The secondary hot press is used for flattening to ensure the uniformity of the template, good bonding strength and viscosity, and uniformity.

Features & Advantages

1.The surface of melamine faced concrete formwork plywood is easy to clean with water or steam,it helps to provide engineering construction efficiency.

2.Durable wear resistant, and is corrosion resistant to ordinary acid and alkali chemicals.It has the characteristics of anti-insect, high hardness and strong stability.

3.Has good freezing resistance and high temperature performance ,good toughness.Used in harsh environments, it still performs very excellent.

4. No shrinkage, no swelling, no cracking, no deformation under high temperature conditions, flameproof and fireproof,and can be used repeatedly for more than 10-15 times.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Brand Name | Heibao | Core | pine, eucalyptus or requested by clients |

| Model Number | Film Faced Plywood | Face/Back | Black(faced phenolic glue) |

| Grade | First-Class | Glue | MR, melamine, WBP, phenolic |

| Size | 1830mm*915mm/1220mm*2440mm | Moisture content | 5%-14% |

| Thickness | 18mm or as required | Delivery Time | Within 20 days after order confirmed |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Usage | Outdoor, construction, bridge beams, etc. | Payment Terms | T/T, L/C |

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for China Wholesale Wood Core Plywood Factories - Melamine Faced Concrete Formwork Plywood – Xinbailin , The product will supply to all over the world, such as: Romania, Canada, Egypt, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.