China Wholesale Veneered Plywood Sheets Suppliers - Phenolic Red Film Faced Plywood for Construction – Xinbailin

China Wholesale Veneered Plywood Sheets Suppliers - Phenolic Red Film Faced Plywood for Construction – Xinbailin Detail:

Process Features

1. Use good pine and eucalyptus whole core boards, and there are no holes in the middle of the blank boards after sawing;

2. The surface coating of the construction plywood is phenolic resin glue with strong waterproof performance, and the core board adopts three ammonia glue (single-layer glue is up to 0.45KG), and layer-by-layer glue is adopted;

3. First cold-pressed and then hot-pressed, and pressed twice, the construction plywood is glued and the structure is stable.

Problems and Prevention

1. Cracks: Reasons: panel cracks, rubber board cracks. Preventive measures: When screening (when selecting boards), pay attention to pick them out, screen non-destructive plastic boards, and arrange them neatly.

2. Overlap: Reason: plastic board, dry board, the filling is too large (the interval is too large (too small). Preventive measures: fill the hole according to a certain size, and cannot exceed the original hole.

3. White leakage: Reason: It is not uniform enough when the red oil is passed once or twice. Preventive measures: During the inspection, manually add red oil.

4. Explosion board: Reason: wet board (plastic board) is not dry enough. Precautions: Inspect wood core boards when shipping.

5. The board surface is rough: Reason: fill the hole, the wood core board knife tail is thinner. Preventive measures: try to choose a flat wood core board.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | Phenolic Red Film Faced Plywood for Construction | Core | pine, eucalyptus or requested by clients |

| Grade | FIRST-CLASS | Face/Back | Red glue paint(can print logo) |

| Size | 1220*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 11.5mm~18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 9-10 layers | Density | 500-700kg/cbm |

| Thickness Tolerance | +/-0.3mm | Packing | Standard export packing |

| Usage | Outdoor, construction, bridge, etc. | MOQ | 1*20GP. Less is acceptable |

| Delivery Time | Within 20 days after order confirmed | Payment Terms | T/T, L/C |

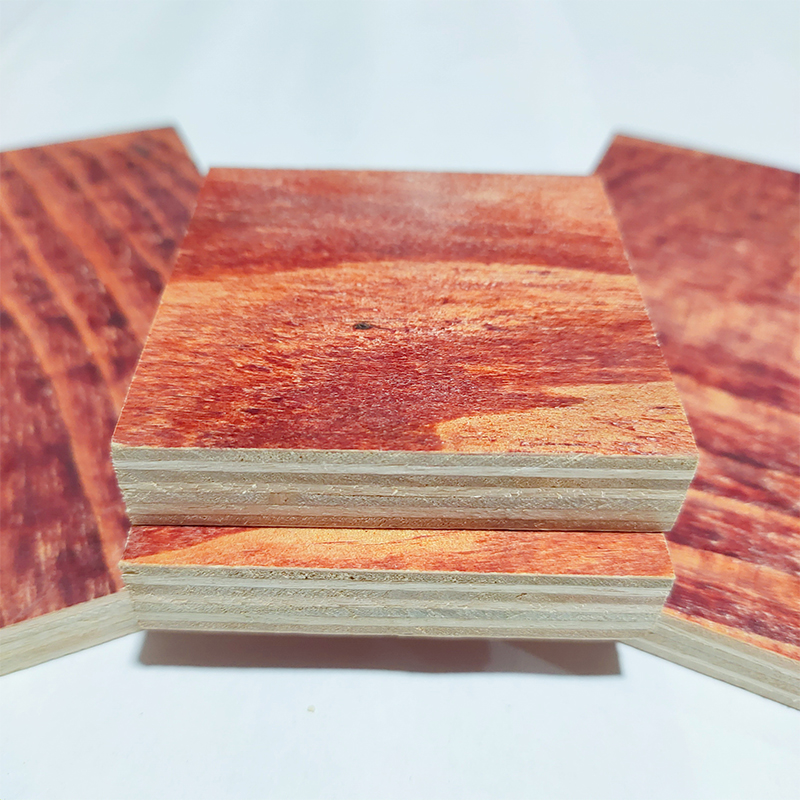

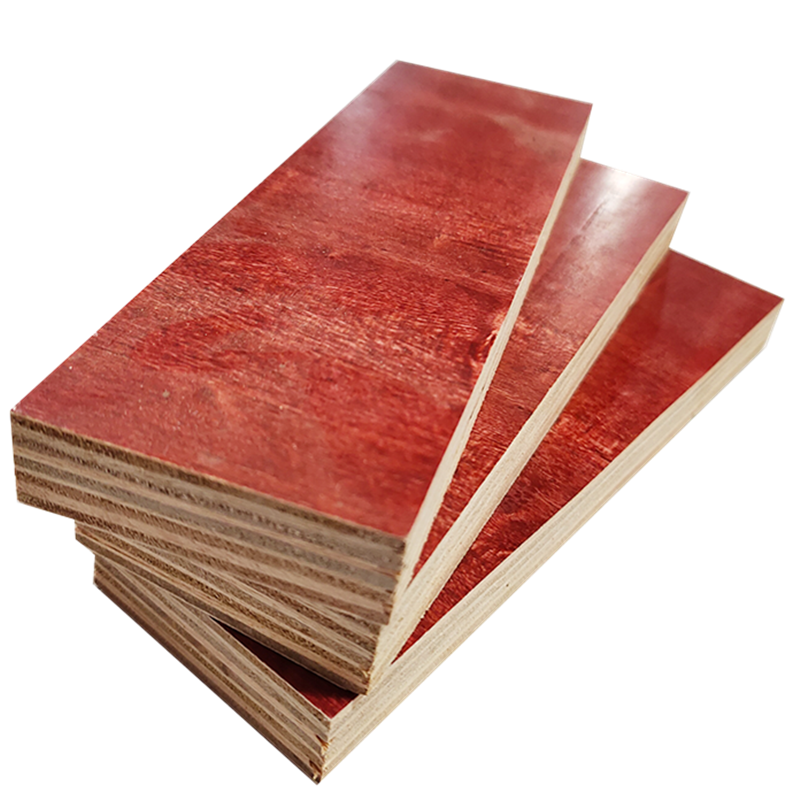

Product detail pictures:

Related Product Guide:

owing to fantastic assistance, a variety of high quality goods, aggressive rates and efficient delivery, we love a very good popularity among our customers. We are an energetic firm with wide market for China Wholesale Veneered Plywood Sheets Suppliers - Phenolic Red Film Faced Plywood for Construction – Xinbailin , The product will supply to all over the world, such as: Indonesia, Jeddah, Gabon, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!