China Wholesale Pp Plastic Coated Plwood Panels Suppliers - Water-Resistant Green PP Plastic Film Faced Formwork Plywood – Xinbailin

China Wholesale Pp Plastic Coated Plwood Panels Suppliers - Water-Resistant Green PP Plastic Film Faced Formwork Plywood – Xinbailin Detail:

Product Detail

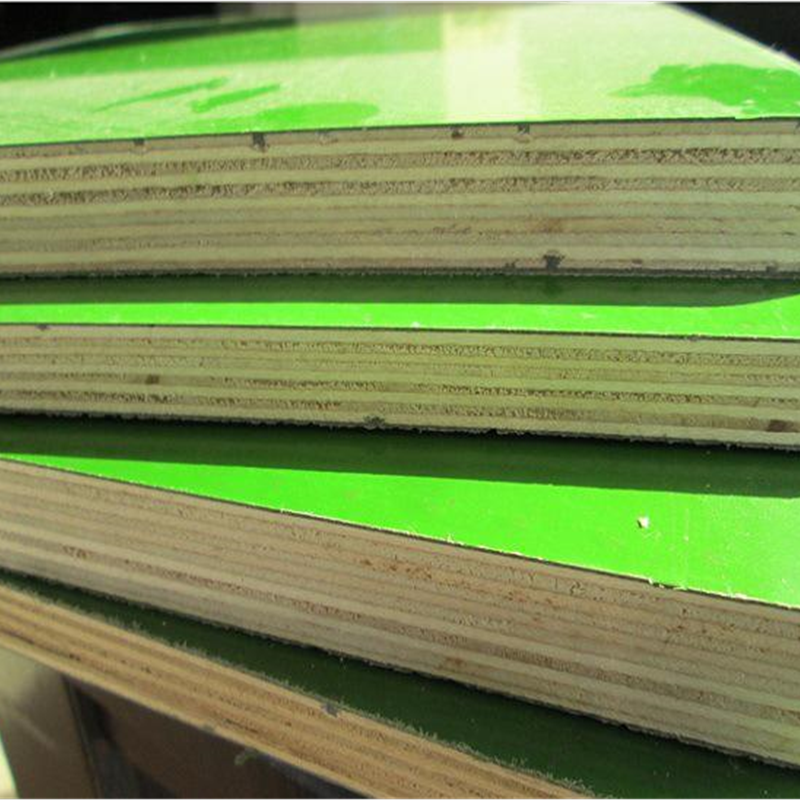

Plastic coated plywood is a new type of environmentally friendly building material. It is another new generation product after wood formwork, combined steel formwork, bamboo and wood glued formwork, and all-steel large formwork. Its interior is made of wood and the surface is covered with plastic (PP). It is widely used in the pouring of concrete square columns, walls, and roofs. It is especially suitable for bridges, high-rises, tunnels and other projects. It combines the characteristics of the wooden formwork and the advantages of the plastic formwork, make it a good formwork for concrete pouring in key projects, which is environmentally friendly and has low amortized cost.

Mainly used in high-rise commercial buildings, pouring roofs, beams, walls, columns, stairs and foundations, bridges and tunnels, water conservancy and hydro-power projects, mines, dams and underground projects.

Plastic coated plywood has become the new favorite of the construction industry for its environmental protection and energy saving, recycling economy and economical benefits, and waterproofing and corrosion resistance.

Eight advantages

1. Smooth and clean

The plywood is spliced tightly and smoothly. After demoulding, the surface and smoothness of the concrete structure exceed the technical requirements of the existing clear water formwork. No secondary plastering is required, which saves labor and materials.

2. Lightweight and easy to install

Light weight, strong process adaptability, can be sawed, planed, drilled, nailed, and can be formed into any geometric shape at will to meet the needs of various shapes of building support.

3. Easy demoulding

The concrete does not stick to the surface of the wood plywood, does not require a release agent, is easily demoulded, and is easy to clean the dust.

4. Stable and weather-resistant

High mechanical strength, no shrinkage, no swelling, no cracking, no deformation, no deformation, size stability, alkali and corrosion resistance, flame retardant and waterproof, resistant to rodents and insects under the temperature conditions of -20℃ to +60℃.

5. Conducive to maintenance

The template does not absorb water and does not require special maintenance or storage.

6. Strong variability

Types, shapes and specifications can be customized according to the requirements of construction projects.

7. Reduce costs

There are many reused times, the plastic coated plywood is no less than 25 times, so the use cost is low.

8. Energy saving and environmental protection

All scraps and used templates can be recycled, with zero waste discharge.

Product Parameter

| Place of Origin | Guangxi, China | Main Material | pine,eucalyptus |

| Brand Name | Heibao | Core | pine, eucalyptus or requested by clients |

| Model Number | Plastic coated plywood | Face/Back | Green Plastic/Custom(can print logo) |

| Grade | FIRST-CLASS | Glue | MR, melamine, WBP, phenolic,etc. |

| Size | 1830mm*915mm | Moisture Content | 5%-14% |

| Thickness | 11.5mm~18mm or as required | Density | 620-680 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Delivery Time | Within 15 days after order confirmed | MOQ | 1*20GP. Less is acceptable |

| Usage | Outdoor, bridges, high-rises, tunnels and other projects, etc. | Payment Terms | T/T, L/C |

Why choose us ?

1. We provide from our own factory directly, giving a rock bottom price, so our price is more competitive.

2. All products are to be produced according to your order including samples.

3. Strict quality control. We're responsible for every batch of shipment.

4. Fast delivery and safe shipping way.

5. We will bring you quality after-sale service.

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for China Wholesale Pp Plastic Coated Plwood Panels Suppliers - Water-Resistant Green PP Plastic Film Faced Formwork Plywood – Xinbailin , The product will supply to all over the world, such as: Israel, Iceland, Kuwait, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, now we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!