China Wholesale Pp Plastic Coated Plwood Panels Manufacturers - Green Plastic Faced Plywood/PP Plastic Coated Plywood Panel – Xinbailin

China Wholesale Pp Plastic Coated Plwood Panels Manufacturers - Green Plastic Faced Plywood/PP Plastic Coated Plywood Panel – Xinbailin Detail:

Product Details

PP film 0.5mm/side

Special PP nail

Hole in wood board

high-quality plywood

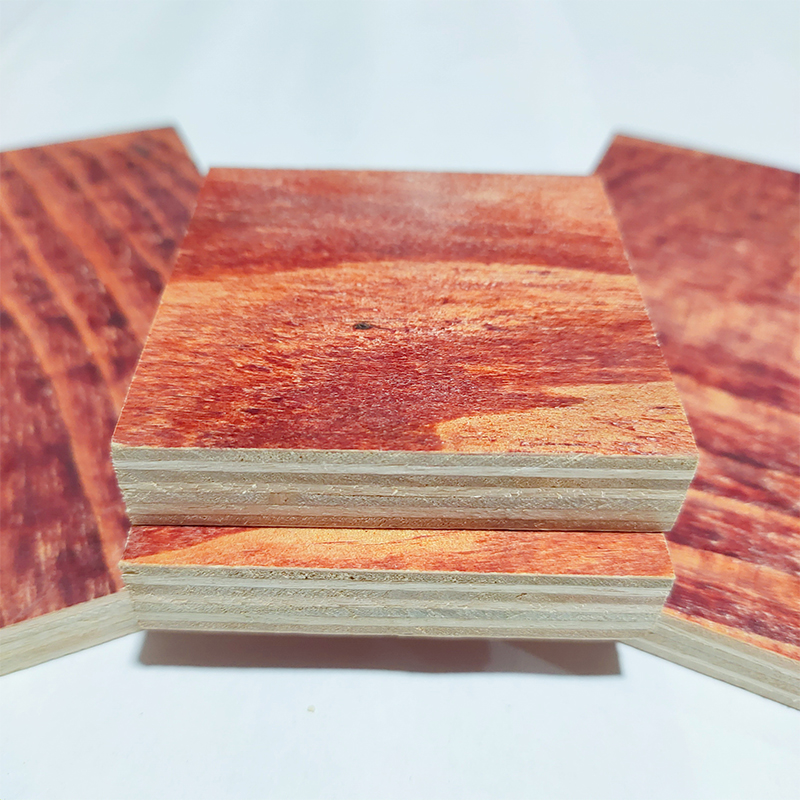

PP plastic coated plwood panels are made of waterproof and durable PP plastic (0.5mm thick), coated on both sides, and is closely connected with the inner plywood core after hot pressing.

PP is also called polypropylene, it has physical properties: corrosion resistance, acid and alkali resistance, hardness and so on.The anhydrous surface is impervious to water and does not stick to cement. It completely protects the inner plywood core, improves static bending strength and turnover times, makes concrete solidification smoother, and increases the number of repeated uses.

The physical and mechanical properties are much higher than traditional film faced plywood. The following excellent performance:

• high mechanical cohesiveness/high strength

• high temperature resistance/corrosion resistance

• high abrasion resistance/excellent chemical resistance

• water and moisture-proof

• recyclable and reusability(more than 25 times)

During the production process, employees are required to arrange boards reasonably to avoid unscientific matching of double boards, stacking of core boards ,and excessive seams between plates

The production operation adopts cold/hot pressing technology, and strictly controls the pressing temperature, pressure intensity, and pressing time to ensure a good compressive strength of the formwork.

The hot-melt adhesive and wood plywood board after hot pressing are pressed together with a pressing machine at a time.After cooling and solidification, the hot-melt adhesive is tightly combined with the plywood surface layer, which is not easy to crack during use.

The products have undergone a number of strict quality inspection procedures,arrange shippment after packing.

Our PP Plastic Coated Plywood have been using widely in construction field around the world, such as Southeast Asia,Europe,etc.

Parameter

| Place of Origin: | Guangxi, China | Main Material: | pine,eucalyptus |

| Brand Name: | Heibao | core: | pine,eucalyptus,or requested by clients |

| Model Number: | Plastic Faced Plywood | face/back: | Green Plastic/Custom(can print logo) |

| Grade: | FIRST-CLASS | glue: | MR, melamine, WBP, phenolic |

| size: | 1830x915mm/1220x2440mm | moisture content: | 5%-14% |

| Thickness: | 11mm-18mm or as required | density | 600-640 kg/cbm |

| Number of Plies | 8-11 layers | Cycle life: | Turnover more than 25 times |

| Thickness Tolerance | +/-0.3mm | Packing | Standard Export Pallet Packing |

| Formaldehyde Release | E2≤5.0mg/L | MOQ: | 1*20GP. Less is acceptable |

| Usage: | Outdoor,construction,bridge,etc | Payment Terms: | T/T, L/C |

| Delivery Time: | Within 20 days after order confirmed | ||

| Loading Quantity: | 20’GP-8pallets/22CBM, 40’HQ-18pallets/53CBM |

Product detail pictures:

Related Product Guide:

Bear "Customer 1st, Good quality first" in mind, we work closely with our prospects and supply them with efficient and professional services for China Wholesale Pp Plastic Coated Plwood Panels Manufacturers - Green Plastic Faced Plywood/PP Plastic Coated Plywood Panel – Xinbailin , The product will supply to all over the world, such as: Bangalore, Austria, Sao Paulo, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.