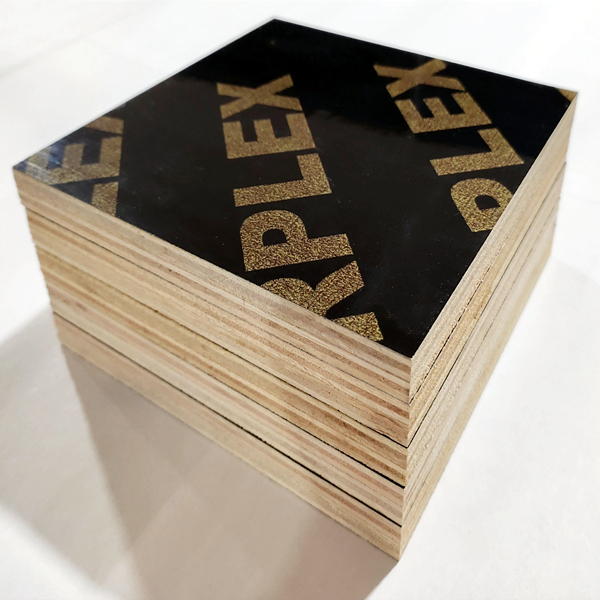

China Wholesale Poplar Plywood Sheets Suppliers - Film Faced Plywood Black Board – Xinbailin

China Wholesale Poplar Plywood Sheets Suppliers - Film Faced Plywood Black Board – Xinbailin Detail:

How to improve the selection ability of wooden formwork,please look at the following aspects:

First of all, please check whether the surface of the wooden template is smooth and flat.Smooth and flat, making it easy to demold during use, the surface of the concrete is smooth, and it also indicates the amount of glue on the surface (the more the amount of glue, the brighter and flatter the surface).Secondly,whether the assembly is uniform during the production process (unbalanced, pressed out of the board) It is not flat).Finally,Whether the thickness of the board edge is the same. If the board-to-board tolerance is large, the concrete surface will not be on the same horizontal line.

1.Clean the board surface before use

2.When unloading the mold, two workers cooperate and pry the two ends of the board at the same time, and try to let the whole board fall horizontally.

3.If there is a crack on the edge, saw it off during the cleaning process.

| Place of Origin: | Guangxi, China | Main Material: | pine,eucalyptus |

| Brand Name: | Heibao | core: | pine,eucalyptus,or requested by clients |

| Model Number: | Film Faced Plywood | face/back: | Black(faced phenolic glue) |

| Grade: | FIRST-CLASS | glue: | MR, melamine, WBP, phenolic |

| size: | 1830mmx915mm/1220mmx2440mm | moisture content: | 5%-14% |

| Thickness: | 11mm~18mm or as required | density | 610-685 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Usage: | Outdoor,construction,road ,etc | Payment Terms: | T/T, L/C |

| Delivery Time: | Within 15 days after order confirmed | MOQ: | 1*20GP. Less is acceptable |

Product detail pictures:

Related Product Guide:

No matter new shopper or old customer, We believe in very long expression and dependable relationship for China Wholesale Poplar Plywood Sheets Suppliers - Film Faced Plywood Black Board – Xinbailin , The product will supply to all over the world, such as: Plymouth, Detroit, Puerto Rico, To work with an excellent products manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!