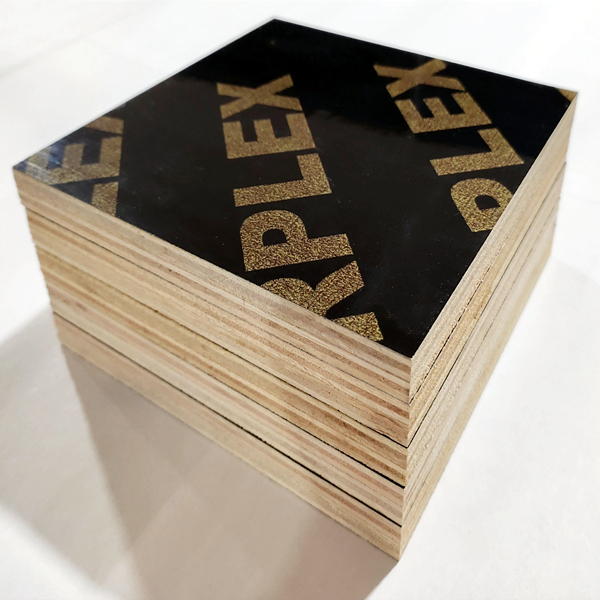

China Wholesale Plywood Mdf Particle Board Factories - Super Smooth Film Faced Plywood – Xinbailin

China Wholesale Plywood Mdf Particle Board Factories - Super Smooth Film Faced Plywood – Xinbailin Detail:

Distinguish the difference between construction wooden formwork:

First of all, see if there is an open space for drying raw materials. Because all the raw materials need to be dried before they can be used in the workshop, the weight difference between the dried raw material and the undried raw material is 2 tons. It sounds unbelievable, but the facts prove that the moisture in the slab will be diluted. The degree of adhesion of the glue will cause the template to degummed. Second, check the quality of the materials. The raw materials are divided into 1/2/3 grades. The first-class material is no damage, no holes, and it is a whole panel. The secondary raw material is broken but there are no holes, and the tertiary raw material is broken with holes. High-quality templates are made of first-class raw materials. Without good raw materials, it is impossible to make good products.

Choose according to different projects:

Housing construction should use medium-sized combined building templates, because the cross-sections of beams and columns vary a lot, and it is not suitable to use multi-layer laminate cutting.

Wall membranes should use a medium-sized combination, because in the same high-rise building group, there are requirements to be unified,so the medium-sized combination helps to ensure a higher reuse rate.

"Hydraulic climbing formwork" is used for super high-rise or high-rise buildings. The climbing formwork combines the advantages of large formwork and sliding formwork. It can rise layer by layer with the construction of the structure, which speeds up the construction speed and saves space and crane lifting times. Conducive to the safety of high-altitude operations.

The overall multi-layer board is used for the construction of the floor building template, and the multi-layer phenolic glue template with a thickness of 15-18mm is used as much as possible. The thick side of this kind of building template will be damaged after repeated use, so it must be cut in time to ensure that the edges of the multilayer board are flat.

Product Parameter

| Place of Origin: | Guangxi, China | Main Material: | pine,eucalyptus |

| Brand Name: | Heibao | core: | pine,eucalyptus,or requested by clients |

| Model Number: | Film Faced Plywood | face/back: | black(can print log) |

| Grade: | FIRST-CLASS | glue: | MR, melamine, WBP, phenolic |

| size: | 1830x915mm/1220x2440mm | moisture content: | 5%-14% |

| Thickness: | 15mm or as required | density | 590-675 kg/cbm |

| Number of Plies | 10 layers | Packing | Standard export packing |

| Thickness Tolerance | +/-0.3mm | MOQ: | 1*20GP. Less is acceptable |

| Usage: | Outdoor,construction,bridge,etc | Payment Terms: | T/T, L/C |

| Delivery Time: | Within 20 days after order confirmed |

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine regularly for China Wholesale Plywood Mdf Particle Board Factories - Super Smooth Film Faced Plywood – Xinbailin , The product will supply to all over the world, such as: Gambia, South Africa, Chicago, We have advanced production technology, and pursuit innovative in goods. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you need to be willing to become partners with us. Looking forward to your inquiry.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.