China Wholesale Plywood For Formworks Suppliers - Black Brazil Film Faced Plywood for Construction – Xinbailin

China Wholesale Plywood For Formworks Suppliers - Black Brazil Film Faced Plywood for Construction – Xinbailin Detail:

Product Description

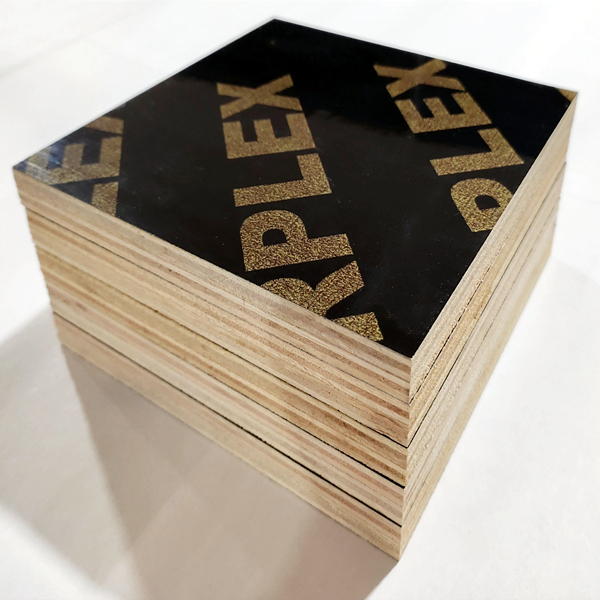

There are no gaps on the side to prevent rainwater from entering. It has good waterproof performance and the surface is not easy to wrinkle. Therefore, it is used more frequently than ordinary laminated panels. It can be used in areas with harsh weather and is not easy to crack and not deform.

The black film faced laminates are mainly 1830mm*915mm and 1220mm*2440mm, which can be produced according to the thickness requirements of 8-11 layers of customers. The secondary hot press is used for flattening to ensure the uniformity of the template, good bonding strength and viscosity, and uniformity.

Product Advantages

1. The quality of our board plywood is stable, the initial adhesion is ≧6N, and the tensile resistance is good.

2. The use performance is high, the wooden template is not deformed or warped, and can be reused many times.

3. The thickness of the board is uniform and the special glue is used. Ensure that the core board material is grade A, and thickness of the product meet to requirements.

4. The template does not crack, with strong elastic modulus, water resistance and corrosion resistance.

5. Customized size are available. Strong and rigid/easy to clean and cut/good chemical resistance

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | Black Brazil Film Faced Plywood for Construction | Core | pine, eucalyptus or requested by clients |

| Grade | First-Class | Face/Back | Black(Black Brazil Film) |

| Size | 1830mm*915mm/1220mm*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 8-11 layers | Delivery Time | Within 20 days after order confirmed |

| Usage | Outdoor, construction, bridge beams, etc. | Packing | Standard export packing |

| Density | 500-700 kg/cbm | Payment Terms | T/T, L/C |

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for China Wholesale Plywood For Formworks Suppliers - Black Brazil Film Faced Plywood for Construction – Xinbailin , The product will supply to all over the world, such as: New Orleans, Bangladesh, Brazil, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.