China Wholesale Plywood Company Factories - High Quality Black Film Faced Plywood For Construction – Xinbailin

China Wholesale Plywood Company Factories - High Quality Black Film Faced Plywood For Construction – Xinbailin Detail:

Product Description

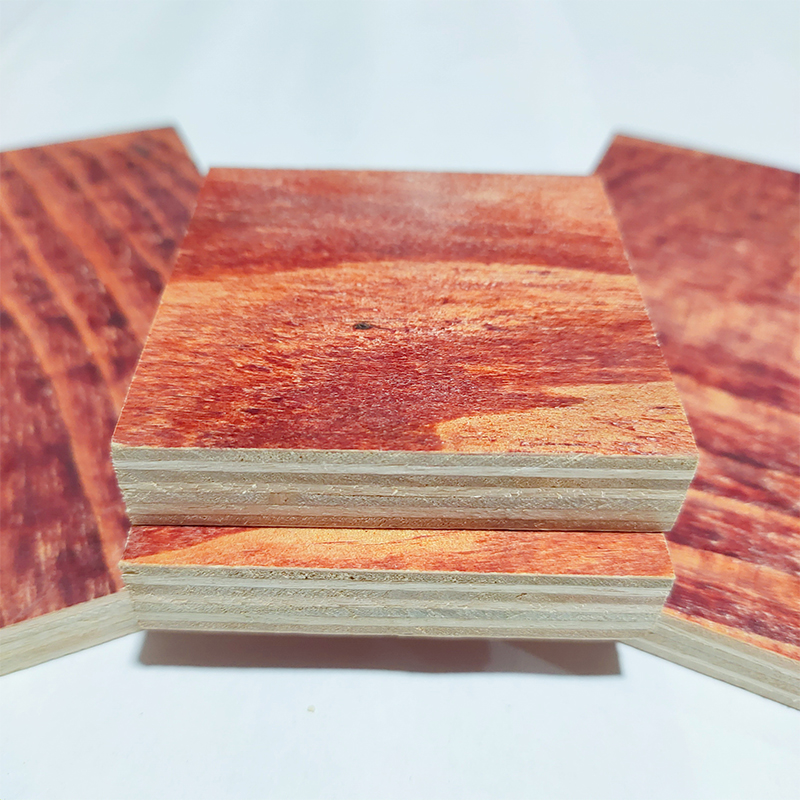

There are no gaps on the side to prevent rainwater from entering. It has good waterproof performance and the surface is not easy to wrinkle. Therefore, it is used more frequently than ordinary laminated panels. It can be used in areas with harsh weather and is not easy to crack and not deform.

The black film faced laminates are mainly 1830mm*915mm and 1220mm*2440mm, which can be produced according to the thickness requirements of 8-11 layers of customers. The secondary hot press is used for flattening to ensure the uniformity of the template, good bonding strength and viscosity, and uniformity.

Frequently Asked Questions

1. Cracks: Reasons: panel cracks, rubber board cracks. Preventive measures: When screening (when selecting boards), pay attention to pick them out, screen non-destructive plastic boards, and arrange them neatly.

2. Overlap: Reason: plastic board, dry board, the filling is too large (the interval is too large (too small). Preventive measures: fill the hole according to a certain size, and cannot exceed the original hole.

3. White leakage: Reason: It is not uniform enough when the red oil is passed once or twice. Preventive measures: During the inspection, manually add red oil.

4. Explosion board: Reason: wet board (plastic board) is not dry enough. Precautions: Inspect wood core boards when shipping.

5. The board surface is rough: Reason: fill the hole, the wood core board knife tail is thinner. Preventive measures: try to choose a flat wood core board.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | High Quality Black Film Faced Plywood For Constructions | Core | pine, eucalyptus or requested by clients |

| Grade | First-Class | Face/Back | Black |

| Size | 1830mm*915mm/1220mm*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 8-11 layers | Delivery Time | Within 20 days after order confirmed |

| Usage | Outdoor, construction, bridge beams, etc. | Packing | Standard export packing |

| Density | 500-700 kg/cbm | Payment Terms | T/T, L/C |

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for China Wholesale Plywood Company Factories - High Quality Black Film Faced Plywood For Construction – Xinbailin , The product will supply to all over the world, such as: Auckland, San Diego, Turkey, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.