China Wholesale Melamine Veneer Suppliers - 15mm Formwork Phenolic Brown Film Faced Plywood – Xinbailin

China Wholesale Melamine Veneer Suppliers - 15mm Formwork Phenolic Brown Film Faced Plywood – Xinbailin Detail:

Product Description

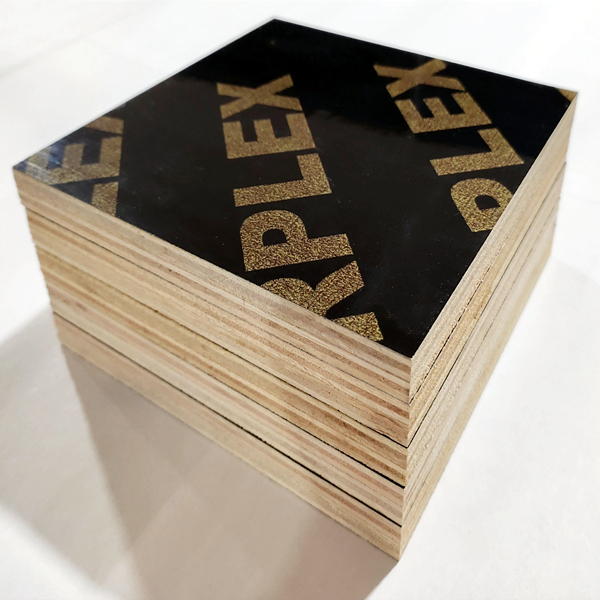

The surface of this 15mm Formwork Phenolic Brown Film Faced Plywood is highly resistant to corrosion and moisture, smooth and easy to peel from formwork cement and easy to clean. The core is waterproof and won't swell, strong enough not to break. The edges of the brown film-faced plywood are coated with a water-repellent paint.

Product Advantages

• Dimension: 1220 x 2440mm(4’x8’) or 1830x915mm(3’x6’) (other cut dimension pls request)

• Thickness tolerance: +/- 0.02m for 100 sheets

• Core material: High-quality Pine and Eucalyptus

• Density: > 650kg/CBM (can be > 700kg/CBM)

• Glue: MR E0/E1,melamine glue ,WBP for exterior

• High pressure pressing for strong bonding

• Eco friendly, using only plantation wood material

• Borer, termites and fungus resistant as request

• Certificate: FSC,EPA CARB P2/TSCA T6 if require

• Cutting into sizes, drilling, edge banding putting, etc as request

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus,or requested |

| Model Number | 15mm Formwork Phenolic Brown Film Faced Plywood | Core | pine, eucalyptus or requested by clients |

| Grade/Certificate | FIRST-CLASS/FSC or requested | Face/Back | brown(can print log) |

| Size | 1830*915mm/1220*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 11.5mm~18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 8-11 layers | Density | 600-690 kg/cbm |

| Thickness Tolerance | +/-0.2mm | Packing | Standard export packing |

| Usage | Outdoor, construction, bridge, etc. | MOQ | 1*20GP. Less is acceptable |

| Delivery Time | Within 20 days after order confirmed | Payment Terms | T/T, L/C |

FQA

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Product detail pictures:

Related Product Guide:

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for China Wholesale Melamine Veneer Suppliers - 15mm Formwork Phenolic Brown Film Faced Plywood – Xinbailin , The product will supply to all over the world, such as: Iran, Nigeria, Iraq, We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!