China Wholesale Melamine Faced Plywood Suppliers - Black Film Color Veneer Board Film Faced Plywood for Concrete and Construction – Xinbailin

China Wholesale Melamine Faced Plywood Suppliers - Black Film Color Veneer Board Film Faced Plywood for Concrete and Construction – Xinbailin Detail:

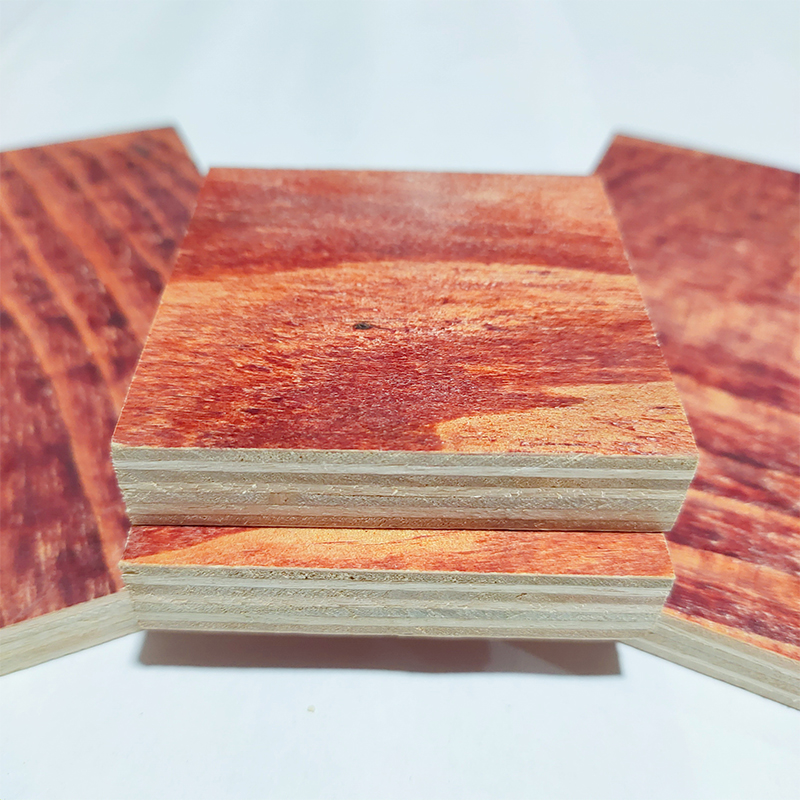

Melamine Faced Boards

The film faced plywood is a film on both sides of the original board, which can increase the template’s reuse rate. It is usually a black film. The film panel uses high-quality pine and eucalyptus as raw materials, uses high-quality special and sufficient glue, and adopts a new type of plywood steaming machine to ensure uniform glue application and improve product quality. During the production process, employees are required to arrange the boards reasonably to avoid problems such as unscientific matching of double boards, stacking of core boards, and excessive seams between boards.

The production operation adopts cold/hot pressing technology to strictly control the pressing temperature, pressure intensity and pressing time to ensure that the template has good compressive strength. After 28 procedures, two times of pressing, five times of inspection and high-precision size can be packaged. Properties determined by mechanical testing: stable quality, initial adhesion ≧ 6N, good tensile resistance; high performance, the wooden template does not deform or warp, high reuse rate. The board thickness is uniform and special glue is used. Ensure that the core board is Grade A and the product thickness meets the requirements. The template does not crack, has a strong elastic modulus, is easy to clean and cut, is strong and hard, is waterproof, flameproof,fireproof and corrosion-resistant.

Parameter:

|

item |

value |

item |

value |

|

Place of Origin: |

Guangxi, China |

Main Material: |

pine,eucalyptus |

|

Brand Name: |

Heibao |

core: |

pine,eucalyptus,or requested by clients |

|

Model Number: |

Film Faced Plywood |

face/back: |

black film (Phenolic glue film) |

|

Grade: |

FIRST-CLASS |

glue: |

MR, melamine, WBP, phenolic |

|

size: |

1830x915mm/1220x2440mm |

moisture content: |

5%-14% |

|

Thickness: |

11.5mm~18mm or as required |

density |

615-685 kg/cbm |

|

Number of Plies |

8-11 layers |

Packing |

Standard export packing |

|

Thickness Tolerance |

+/-0.2mm |

MOQ: |

1*20GP. Less is acceptable |

|

Usage: |

Outdoor,construction,bridge,etc |

Payment Terms: |

T/T, L/C |

|

Delivery Time: |

Within 15 days after order confirmed |

Product detail pictures:

Related Product Guide:

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for China Wholesale Melamine Faced Plywood Suppliers - Black Film Color Veneer Board Film Faced Plywood for Concrete and Construction – Xinbailin , The product will supply to all over the world, such as: New Delhi, Marseille, Azerbaijan, We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!