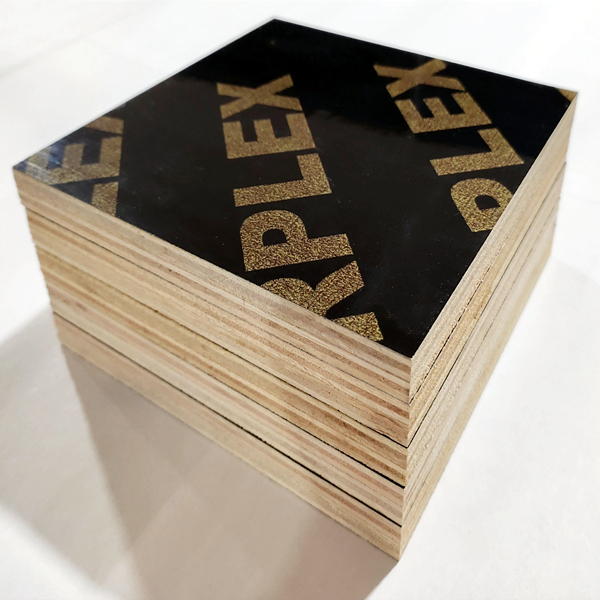

China Wholesale Marine Plywood 18mm Factories - Film Faced Plywood Black Board – Xinbailin

China Wholesale Marine Plywood 18mm Factories - Film Faced Plywood Black Board – Xinbailin Detail:

Product Details

How to improve the selection ability of wooden formwork, please look at the following aspects:

First of all, please check whether the surface of the wooden template is smooth and flat: smooth and flat, making it easy to demold during use, the surface of the concrete is smooth, and it also indicates the amount of glue on the surface (the more amount of glue, the brighter and flatter the surface). Secondly, whether the assembly is uniform during the production process(unbalanced, pressed out of the board, it is not flat). Finally, whether the thickness of the board edge is the same. If the board-to-board tolerance is large, the concrete surface will not be on the same horizontal line.

Maintenance tips

1. Clean the board surface before use.

2. When unloading the mold, two workers cooperate and pry the two ends of the board at the same time, and try to let the whole board fall horizontally.

3. If there is a crack on the edge, saw it off during the cleaning process.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Brand Name | Heibao | Core | pine, eucalyptus or requested by clients |

| Model Number | Film Faced Plywood | Face/Back | Black(faced phenolic glue) |

| Grade | FIRST-CLASS | Glue | MR, melamine, WBP, phenolic |

| Size | 1830mm*915mm/1220mm*2440mm | Moisture content | 5%-14% |

| Thickness | 11mm~18mm or as required | Density | 610-685 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Usage | Outdoor, construction, road, etc. | Payment Terms | T/T, L/C |

| Delivery Time | Within 15 days after order confirmed | MOQ | 1*20GP. Less is acceptable |

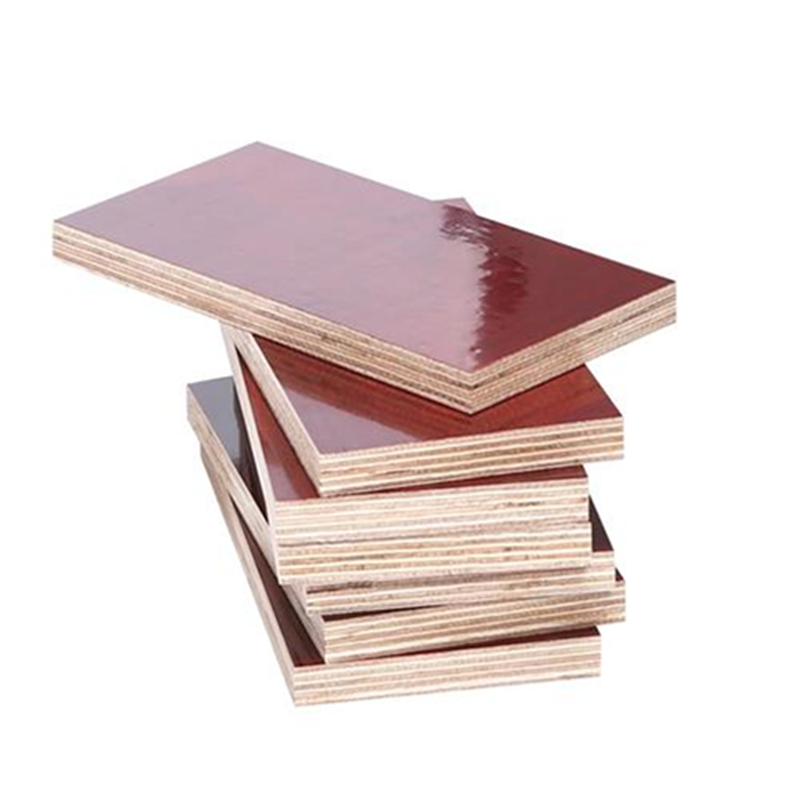

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for China Wholesale Marine Plywood 18mm Factories - Film Faced Plywood Black Board – Xinbailin , The product will supply to all over the world, such as: Washington, Australia, Oman, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.