China Wholesale Formwork Plywood Factories - 18mm Film Faced Plywood Film Faced Plywood Standard – Xinbailin

China Wholesale Formwork Plywood Factories - 18mm Film Faced Plywood Film Faced Plywood Standard – Xinbailin Detail:

Product Description

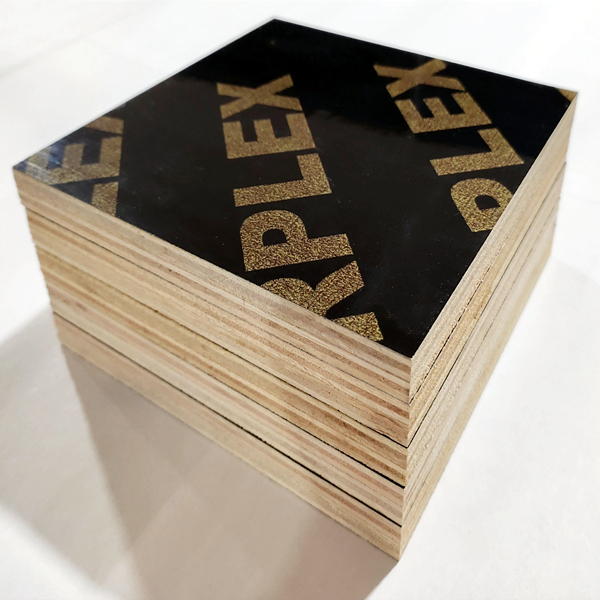

The 18mm film faced plywood selects high-quality pine & eucalyptus as raw materials; High-quality and sufficient glue is used, and equipped with professionals to adjust the glue; A new type of plywood glue cooking machine is used to ensure uniform glue brushing and improve product quality.

During the production process, employees are required to arrange boards reasonably to avoid unscientific matching of double boards, stacking of core boards, and excessive seams between plates.

The production operation adopts cold/hot pressing technology, and strictly controls the pressing temperature, pressure intensity, and pressing time to ensure a good compressive strength of the plates.

The products have undergone a number of strict quality inspection procedures, arrange shipment after packing.

Product Advantages

1. Select high-quality eucalyptus veneer, first-class panel, good materials can make good products

2. The amount of glue is sufficient, and each board is 5 taels more glue than normal boards

3. Strict management system to ensure that the discharged board surface is flat and the sawing density is good.

4. The pressure is high.

5. The product is not deformed or warped, the thickness is uniform, and the board surface is smooth.

6. The glue is made of melamine according to the national standard of 13%, and the product is resistant to sunlight, water and moisture.

7. Wear-resistant, heat-resistant, durable, no degumming, no peeling, can be used repeatedly for more than 16 times.

8. Good toughness, high strength and high usage times.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | 18mm Film Faced Plywood Film Faced Plywood Standard | Core | pine, eucalyptus or requested by clients |

| Grade | First-Class | Face/Back | Black(Black Brazil Film) |

| Size | 1830mm*915mm/1220mm*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 8-11 layers | Delivery Time | Within 20 days after order confirmed |

| Usage | Outdoor, construction, bridge beams, etc. | Packing | Standard export packing |

| Density | 500-700 kg/cbm | Payment Terms | T/T, L/C |

Product detail pictures:

Related Product Guide:

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for China Wholesale Formwork Plywood Factories - 18mm Film Faced Plywood Film Faced Plywood Standard – Xinbailin , The product will supply to all over the world, such as: Czech Republic, Moscow, Congo, With the effort to keep pace with world's trend, we'll always endeavor to meet customers' demands. If you want develop any other new items, we can customize them to suit your needs. If you feel interest in any of our products and solutions or want develop new merchandise, you should feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.