China Wholesale Film Faced Panel Manufacturers - Concrete Formwork Wood Plywood – Xinbailin

China Wholesale Film Faced Panel Manufacturers - Concrete Formwork Wood Plywood – Xinbailin Detail:

Product Description

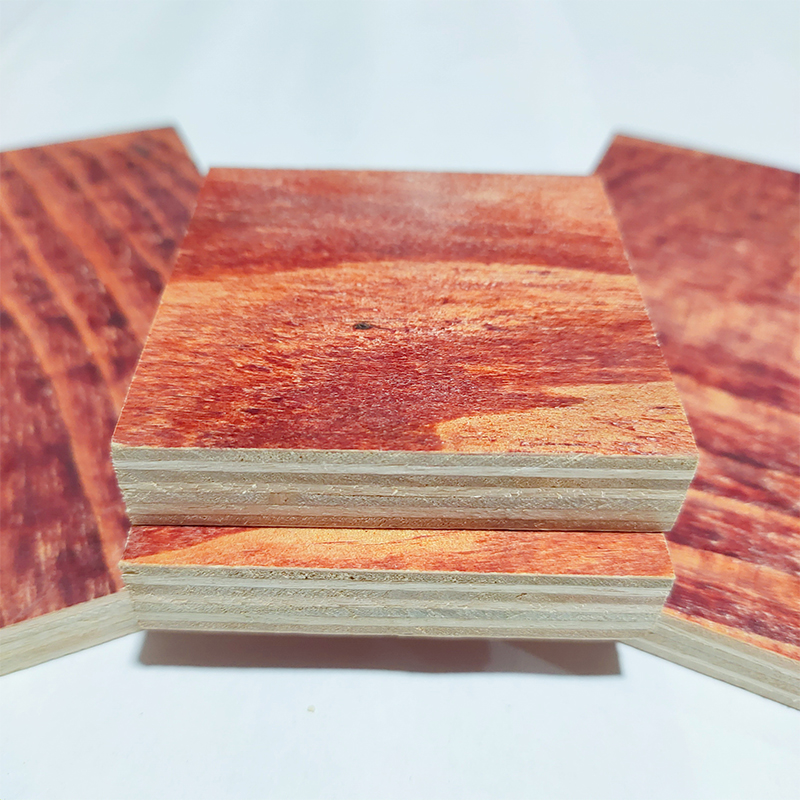

Our film faced plywood has good durability, is not easy to deform, does not warp, and it can be reused up to 15-20 times, which is environmentally friendly and the price is affordable.

The film faced plywood selects high-quality pine & eucalyptus as raw materials; High-quality and sufficient glue is used, and equipped with professionals to adjust the glue; A new type of plywood glue cooking machine is used to ensure uniform glue brushing and improve product quality.

During the production process, employees are required to arrange boards reasonably to avoid unscientific matching of double boards, stacking of core boards, and excessive seams between plates.

The production operation adopts cold/hot pressing technology, and strictly controls the pressing temperature, pressure intensity, and pressing time to ensure a good compressive strength of the plates.

The products have undergone a number of strict quality inspection procedures, arrange shipment after packing.

Company

Our trading company mainly acts as an agent for the building templates directly sold by Heibao factory. Our templates are used for house construction, bridge beams, road construction, big concrete projects, etc.

Our products are exported to Japan, UK, Vietnam, etc.

There are more than 2,000 construction purchasers in cooperation with Heibao Wood industry. At present, the company is striving to expand its scale, focusing on brand development, and creating a good cooperation environment.

The advantages of our product

1. The quality of our board plywood is stable, the initial adhesion is ≧6N, and the tensile resistance is good.

2. The use performance is high, the wooden template is not deformed or warped, and can be reused many times.

3. The thickness of the board is uniform and the special glue is used. Ensure that the core board material is grade A, and thickness of the product meet to requirements.

4. The template does not crack, with strong elastic modulus, water resistance and corrosion resistance.

5. Customized size are available. Strong and rigid/Easy to clean and cut/Good chemical resistance.

Guaranteed Quality

1.Certification: CE, FSC, ISO, etc..

2. It is made of materials with a thickness of 1.0-1.2mm, which is 30%-50% more durable than the templates on the market.

3. The core board is made of environmentally friendly materials, uniform material, and the template does not bonding gap or warpage.

Success Cases

Xiangxi County, Beijing

Jianshui Yanqi, Beijing

Zengcheng Garden Project, Guangdong

Project of Dalian

Eucalyptus template sent to Jingdezhen, Jiangxi

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Brand Name | Monster | Core | pine, eucalyptus or requested by clients |

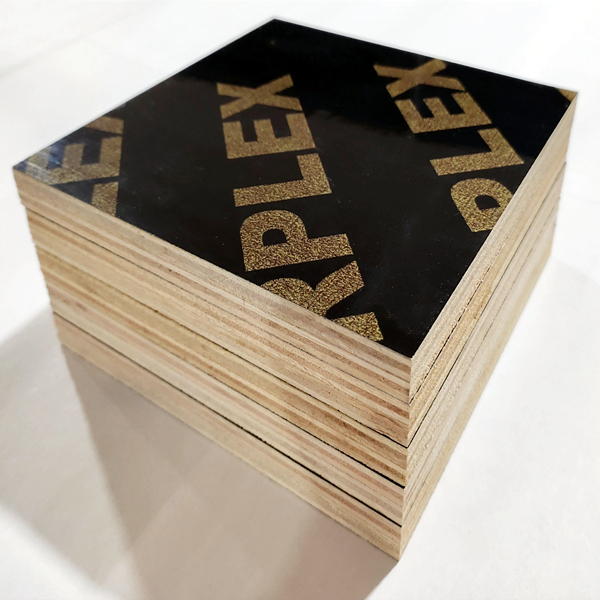

| Model Number | Film Faced Plywood | Face/Back | black(can print log) |

| Grade/Certificate | FIRST-CLASS/FSC or requested | Glue | MR, melamine, WBP, phenolic |

| Size | 1830*915mm/1220*2440mm | Moisture content | 5%-14% |

| Thickness | 11.5mm~18mm or as required | Density | 600-690 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Thickness Tolerance | +/-0.3mm | MOQ | 1*20GP. Less is acceptable |

| Usage | Outdoor, construction, bridge, etc. | Payment Terms | T/T, L/C |

| Delivery Time | Within 20 days after order confirmed |

FQA

Q: What are your advantages?

A: 1) Our factories have more than 20 years experiences of producing film faced plywood, laminates, shuttering plywood,melamine plywood,particle board,wood veneer,MDF board,etc.

2) Our products with high-quality raw materials and quality assurance, we are factory-directly sale.

3) We can produce 20000 CBM per month, so your order will be delivered in a short time.

Q: Could you print the company name and logo on the plywood or packages?

A: Yes, we can print your own logo on plywood and packages.

Q: Why we choose Film Faced Plywood?

A: Film Faced Plywood is better than iron mould and can satisfy the requirements of constructing mould, the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing.

Q: What is the lowest priced film faced plywood?

A: Finger joint core plywood is cheapest in price. Its core is made from recycled plywood so it has low price. Finger joint core plywood can only be used two times in formwork. The difference is that our products are made of high-quality eucalyptus/pine cores, which can increase the reused times by more than 10 times.

Q: Why choose eucalyptus/pine for the material?

A: Eucalyptus wood is denser, harder, and flexible. Pine wood has good stability and ability to withstand lateral pressure.

Product detail pictures:

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for China Wholesale Film Faced Panel Manufacturers - Concrete Formwork Wood Plywood – Xinbailin , The product will supply to all over the world, such as: Morocco, Salt Lake City, Dubai, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.