China Wholesale Eucalyptus Core Plywood Factories - High Level Anti-slip Film Faced Plywood – Xinbailin

China Wholesale Eucalyptus Core Plywood Factories - High Level Anti-slip Film Faced Plywood – Xinbailin Detail:

Product Description

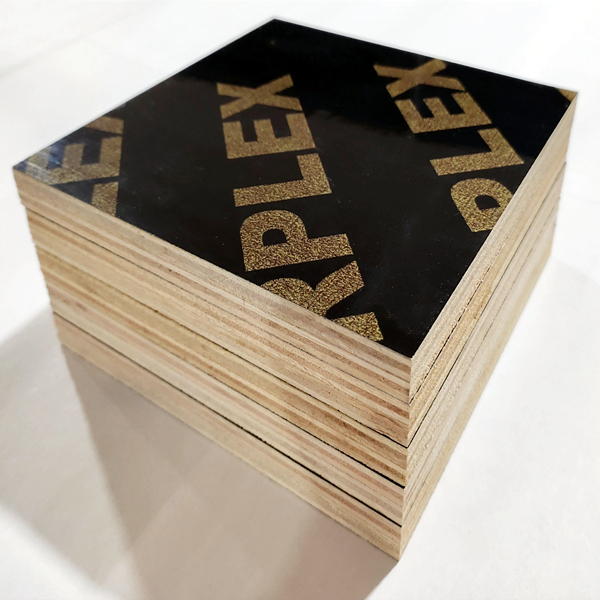

The high level anti-slip film faced plywood selects high-quality pine & eucalyptus as raw materials; High-quality and sufficient glue is used, and equipped with professionals to adjust the glue; A new type of plywood glue cooking machine is used to ensure uniform glue brushing and improve product quality.

During the production process, employees are required to arrange boards reasonably to avoid unscientific matching of double boards, stacking of core boards, and excessive seams between plates.

The production operation adopts cold/hot pressing technology, and strictly controls the pressing temperature, pressure intensity, and pressing time to ensure a good compressive strength of the plates.

The products have undergone a number of strict quality inspection procedures, arrange shipment after packing.

Product Advantages

1.The surface of high level anti-slip film faced plywood has anti-slip function,and it is easy to clean with water or steam,which helps to provide engineering construction efficiency.

2.Durable wear resistant, and is corrosion resistant to ordinary acid and alkali chemicals.It has the characteristics of anti-insect, high hardness and strong stability.

3.Has good freezing resistance and high temperature performance ,good toughness.Used in harsh environments, it still performs very excellent.

4. No shrinkage, no swelling, no cracking, no deformation under high temperature conditions.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | High level anti-slip film faced plywood | Core | pine, eucalyptus or requested by clients |

| Grade | First-Class | Face/Back | Black |

| Size | 1830mm*915mm/1220mm*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 8-11 layers | Delivery Time | Within 20 days after order confirmed |

| Usage | Outdoor, construction, bridge beams, etc. | Packing | Standard export packing |

| Density | 500-700 kg/cbm | Payment Terms | T/T, L/C |

Product detail pictures:

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for China Wholesale Eucalyptus Core Plywood Factories - High Level Anti-slip Film Faced Plywood – Xinbailin , The product will supply to all over the world, such as: Islamabad, Bulgaria, Algeria, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.