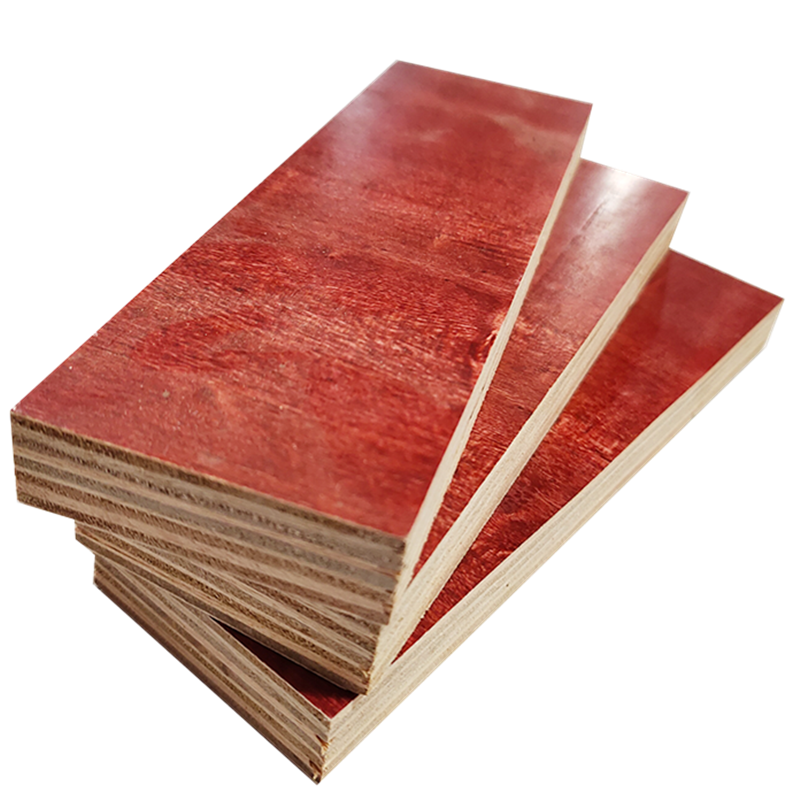

China Wholesale Engineering Red Board Factories - Phenolic Red Film Faced Plywood for Construction – Xinbailin

China Wholesale Engineering Red Board Factories - Phenolic Red Film Faced Plywood for Construction – Xinbailin Detail:

Process Features

1. Use good pine and eucalyptus whole core boards, and there are no holes in the middle of the blank boards after sawing;

2. The surface coating of the construction plywood is phenolic resin glue with strong waterproof performance, and the core board adopts three ammonia glue (single-layer glue is up to 0.45KG), and layer-by-layer glue is adopted;

3. First cold-pressed and then hot-pressed, and pressed twice, the construction plywood is glued and the structure is stable.

Problems and Prevention

1. Cracks: Reasons: panel cracks, rubber board cracks. Preventive measures: When screening (when selecting boards), pay attention to pick them out, screen non-destructive plastic boards, and arrange them neatly.

2. Overlap: Reason: plastic board, dry board, the filling is too large (the interval is too large (too small). Preventive measures: fill the hole according to a certain size, and cannot exceed the original hole.

3. White leakage: Reason: It is not uniform enough when the red oil is passed once or twice. Preventive measures: During the inspection, manually add red oil.

4. Explosion board: Reason: wet board (plastic board) is not dry enough. Precautions: Inspect wood core boards when shipping.

5. The board surface is rough: Reason: fill the hole, the wood core board knife tail is thinner. Preventive measures: try to choose a flat wood core board.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | Phenolic Red Film Faced Plywood for Construction | Core | pine, eucalyptus or requested by clients |

| Grade | FIRST-CLASS | Face/Back | Red glue paint(can print logo) |

| Size | 1220*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 11.5mm~18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 9-10 layers | Density | 500-700kg/cbm |

| Thickness Tolerance | +/-0.3mm | Packing | Standard export packing |

| Usage | Outdoor, construction, bridge, etc. | MOQ | 1*20GP. Less is acceptable |

| Delivery Time | Within 20 days after order confirmed | Payment Terms | T/T, L/C |

Product detail pictures:

Related Product Guide:

Having a positive and progressive attitude to customer's fascination, our organization constantly improves our solution high-quality to fulfill the requirements of shoppers and further focuses on safety, reliability, environmental prerequisites, and innovation of China Wholesale Engineering Red Board Factories - Phenolic Red Film Faced Plywood for Construction – Xinbailin , The product will supply to all over the world, such as: Australia, Indonesia, Lyon, The products has a good reputation with competitive price, unique creation, leading the industry trends. The company insists on the principle of win-win idea, has establishedglobal sales network and after-sales service network.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!