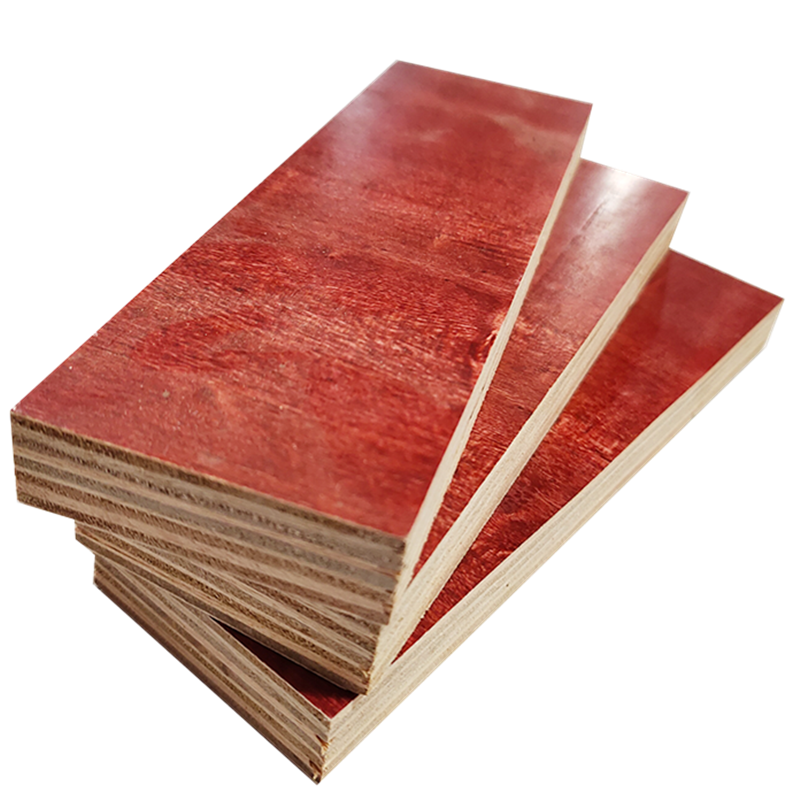

China Wholesale Construction Formwork Factories - Phenolic Red Film Faced Plywood for Construction – Xinbailin

China Wholesale Construction Formwork Factories - Phenolic Red Film Faced Plywood for Construction – Xinbailin Detail:

Process Features

1. Use good pine and eucalyptus whole core boards, and there are no holes in the middle of the blank boards after sawing;

2. The surface coating of the construction plywood is phenolic resin glue with strong waterproof performance, and the core board adopts three ammonia glue (single-layer glue is up to 0.45KG), and layer-by-layer glue is adopted;

3. First cold-pressed and then hot-pressed, and pressed twice, the construction plywood is glued and the structure is stable.

Problems and Prevention

1. Cracks: Reasons: panel cracks, rubber board cracks. Preventive measures: When screening (when selecting boards), pay attention to pick them out, screen non-destructive plastic boards, and arrange them neatly.

2. Overlap: Reason: plastic board, dry board, the filling is too large (the interval is too large (too small). Preventive measures: fill the hole according to a certain size, and cannot exceed the original hole.

3. White leakage: Reason: It is not uniform enough when the red oil is passed once or twice. Preventive measures: During the inspection, manually add red oil.

4. Explosion board: Reason: wet board (plastic board) is not dry enough. Precautions: Inspect wood core boards when shipping.

5. The board surface is rough: Reason: fill the hole, the wood core board knife tail is thinner. Preventive measures: try to choose a flat wood core board.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | Phenolic Red Film Faced Plywood for Construction | Core | pine, eucalyptus or requested by clients |

| Grade | FIRST-CLASS | Face/Back | Red glue paint(can print logo) |

| Size | 1220*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 11.5mm~18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 9-10 layers | Density | 500-700kg/cbm |

| Thickness Tolerance | +/-0.3mm | Packing | Standard export packing |

| Usage | Outdoor, construction, bridge, etc. | MOQ | 1*20GP. Less is acceptable |

| Delivery Time | Within 20 days after order confirmed | Payment Terms | T/T, L/C |

Product detail pictures:

Related Product Guide:

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for China Wholesale Construction Formwork Factories - Phenolic Red Film Faced Plywood for Construction – Xinbailin , The product will supply to all over the world, such as: Bangalore, US, Cape Town, We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!