China Wholesale Concrete Form Plywood Price Factories - Black Film Color Veneer Board Film Faced Plywood for Concrete and Construction – Xinbailin

China Wholesale Concrete Form Plywood Price Factories - Black Film Color Veneer Board Film Faced Plywood for Concrete and Construction – Xinbailin Detail:

Product Details

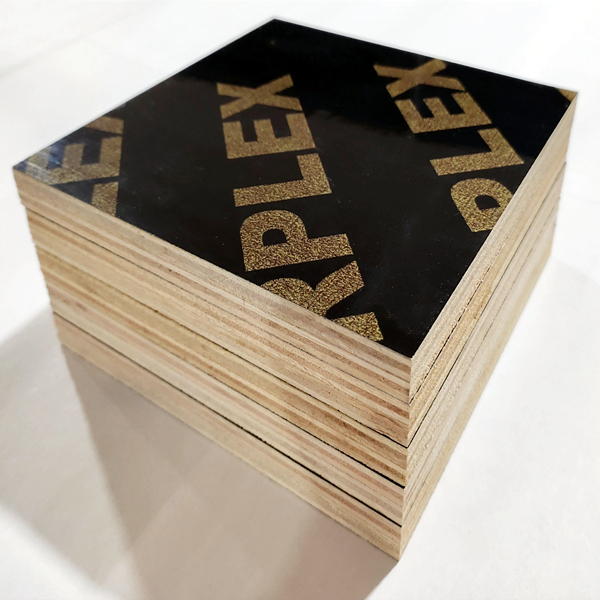

Properties determined by mechanical testing: stable quality, initial adhesion ≧ 6N, good tensile resistance, high performance, the wooden plywood does not deform or warp, high reuse rate. The board thickness is uniform and special glue is used. Ensure that the core board is Grade A and the product thickness meets the requirements. The plywood does not crack, has a strong elastic modulus, is easy to clean and cut, is strong and hard, is waterproof, flameproof, fireproof and corrosion-resistant.

The film faced plywood is a film on both sides of the original board, which can increase the plywood’s reuse rate. It is usually a black film. The film panel uses high-quality pine and eucalyptus as raw materials, uses high-quality special and sufficient glue, and adopts a new type of plywood steaming machine to ensure uniform glue application and improve product quality. During the production process, employees are required to arrange the boards reasonably to avoid problems such as unscientific matching of double boards, stacking of core boards, and excessive seams between boards.

The production operation adopts cold/hot pressing technology to strictly control the pressing temperature, pressure intensity and pressing time to ensure that the plywood has good compressive strength. After 28 procedures, two times of pressing, five times of inspection and high-precision size can be packaged.

Advantage

1.The surface of film faced plywood is smooth,and it is easy to clean with water or steam,which helps to provide engineering construction efficiency.

2.Durable wear resistant, and is corrosion resistant to ordinary acid and alkali chemicals.It has the characteristics of anti-insect, high hardness and strong stability.

3.Has good freezing resistance and high temperature performance ,good toughness.Used in harsh environments, it still performs very excellent.

4. No shrinkage, no swelling, no cracking, no deformation under high temperature conditions.

Parameter

| Item | Value | Item | Value |

| Place of Origin | Guangxi, China | Main Material | Pine,eucalyptus |

| Brand Name | Monster | Core | Pine, eucalyptus or requested by clients |

| Model Number | Veneer Board Film Faced Plywood | Face/Back | Black film (Phenolic glue film) |

| Grade/Certificate | FIRST-CLASS/FSC or requested | Glue | MR, melamine, WBP, phenolic |

| Size | 1830*915mm/1220*2440mm | Moisture Content | 5%-14% |

| Thickness | 11.5mm~18mm or as required | Density | 615-685 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Thickness Tolerance | +/-0.2mm | MOQ | 1*20GP. Less is acceptable |

| Usage | Outdoor, construction, bridge,etc | Payment Terms | T/T, L/C |

| Delivery Time | Within 15 days after order confirmed |

Product detail pictures:

Related Product Guide:

Now we have highly developed devices. Our items are exported towards the USA, the UK and so on, enjoying a great popularity among the customers for China Wholesale Concrete Form Plywood Price Factories - Black Film Color Veneer Board Film Faced Plywood for Concrete and Construction – Xinbailin , The product will supply to all over the world, such as: Ecuador, Italy, Finland, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.