China Wholesale Building Timber Price Factories - Building Red Plank/Concrete Formwork Plywood – Xinbailin

China Wholesale Building Timber Price Factories - Building Red Plank/Concrete Formwork Plywood – Xinbailin Detail:

Product Details

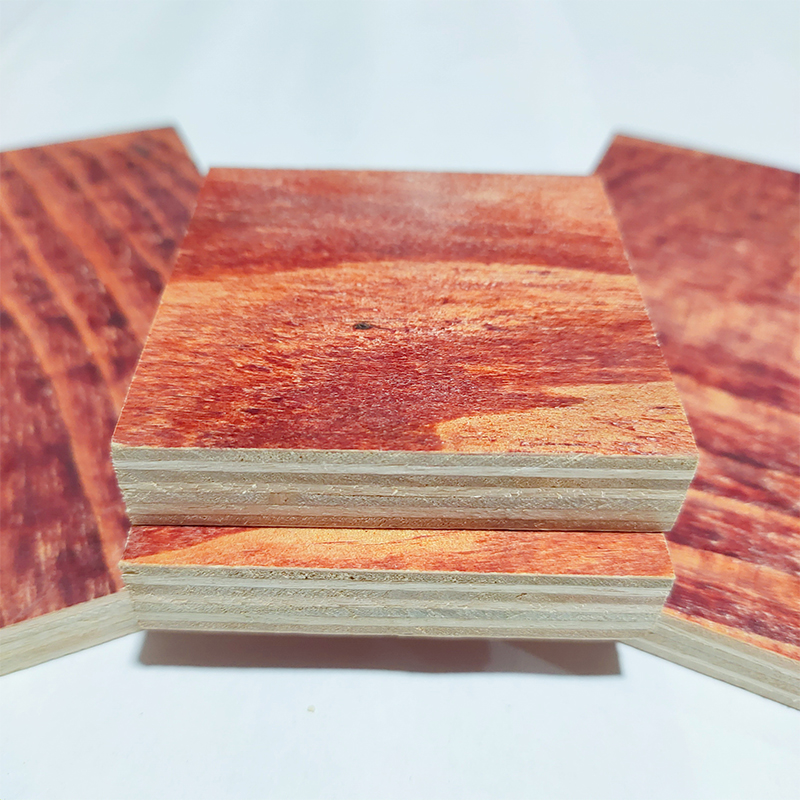

Our building red plank has good durability, is not easy to deform, does not warp, and it can be reused up to 10-18 times, which is environmentally friendly and affordable.

The building red plank selects high-quality pine & eucalyptus as raw materials;High-quality glue/sufficient glue is used, and equipped with professionals to adjust the glue; A new type of plywood glue boiling machine is used to ensure uniform glue brushing and improve product quality.

During the production process, employees are required to arrange boards reasonably to avoid unscientific matching of double boards, stacking of core boards ,and excessive seams between plates.

The production operation adopts cold/hot pressing technology, and strictly controls the pressing temperature, pressure intensity, and pressing time to ensure a good compressive strength of the formwork.

The products have undergone a number of strict quality inspection procedure,arrange shipment after packing.

Features

1. Select high-quality pine wood and eucalyptus wood as raw materials, which have small stuttering and good toughness, and select full-core veneers;

2. The surface coating is phenolic resin glue with strong waterproof performance. The core board adopts special glue (the weight of the glue used for each layer of the board weighs 0.5kg). And the layer-by-layer glue is used, which has strong bonding performance and can increase the turnover of the product.

3. Having the characteristics of flat surface,lighten, high strength, and easy processing

Parameter

| Place of Origin: | Guangxi, China | Main Material: | pine,eucalyptus |

| Brand Name: | Monster | Core: | pine,eucalyptus,or requested by clients |

| Model Number: | concrete formwork plywood | Face/Back: | red(can print logo) |

| Grade/Certificate: | First-Class/FSC or requested | Glue: | MR, melamine, WBP, phenolic |

| Size: | 1830x915mm/1220x2440mm | Moisture content: | 5%-14% |

| Thickness: | 11mm~18mm or as required | Density | 600-675 kg/cbm |

| Number of Plies | 8-11 layers | Packing | standard export packing |

| Thickness Tolerance | +/-0.3mm | MOQ: | 1*20GP. Less is acceptable |

| Usage: | outdoor,construction,road ,etc | Payment Terms: | T/T, L/C |

| Delivery Time: | within 20 days after order confirmed |

Product detail pictures:

Related Product Guide:

Each individual member from our large performance revenue crew values customers' needs and company communication for China Wholesale Building Timber Price Factories - Building Red Plank/Concrete Formwork Plywood – Xinbailin , The product will supply to all over the world, such as: Congo, Bulgaria, Australia, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.