China Wholesale Building Plywood Manufacturers - Phenolic Board for Building Exterior Walls – Xinbailin

China Wholesale Building Plywood Manufacturers - Phenolic Board for Building Exterior Walls – Xinbailin Detail:

Product Description

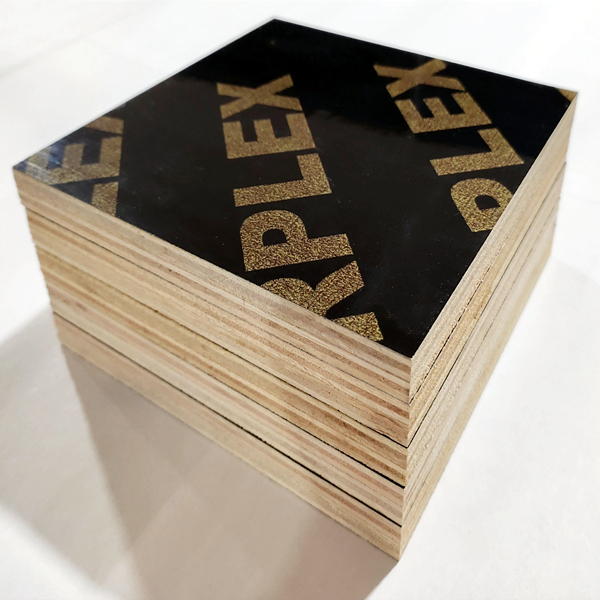

The raw materials used for the phenolic board for exterior walls are also eucalyptus core panels and pine panels, melamine glue, with a uniform structure, and phenolic resin glue is used on the surface, with first-class pine panels, making the surface smooth, waterproof and wear-resistant,even sharp tools are also used. Hardly chipping, cutting, drilling, gluing, driving nails without any problems.In addition, eucalyptus wood has high hardness and stable moisture content, so it can be used normally even in very hot or cold climates, so it is suitable for exterior wall molding and also suitable for humid indoors. Thickness can be customized,up to 20mm thick.

Features & Advantages

1.The surface is coated with phenolic glue twice, which is reddish-brown and has good gloss. The exterior walls of buildings using this product are very smooth, which can greatly improve engineering efficiency and reduce the investment of financial, material and human resources. It is an ideal auxiliary tool for construction projects.

2.Light weight, can be used many times, easy to transport in multiple engineering points.

3.Large size, the common size is 1220mm*2440mm, it is also very convenient and effective to use on the outer wall with a large area, the thickness can be customized between 8mm to 20mm.

4. Low formaldehyde emission, friendly to human and environment.

5. Easy to be moved, which is one of seven to steel form work. It can shorten working time.

6.No pollution on the surface of concrete.

7.It can be made into bending building plywood.

8. Good performance in construction, in nailing, sawing and drilling is far better than bamboo plywood and steel concrete formwork, It can be made into various shape's plywood.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | 12mm Red Film Faced Plywood for Construction | Core | pine, eucalyptus or requested by clients |

| Grade | FIRST-CLASS | Face/Back | Red glue paint(can print logo) |

| Size | 1220*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 11.5mm~18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 9-10 layers | Density | 500-700kg/cbm |

| Thickness Tolerance | +/-0.3mm | Packing | Standard export packing |

| Usage | Outdoor, construction, bridge, etc. | MOQ | 1*20GP. Less is acceptable |

| Delivery Time | Within 20 days after order confirmed | Payment Terms | T/T, L/C |

Product detail pictures:

Related Product Guide:

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for China Wholesale Building Plywood Manufacturers - Phenolic Board for Building Exterior Walls – Xinbailin , The product will supply to all over the world, such as: Oslo, Puerto Rico, Honduras, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!