China Wholesale Birch Plywood Board Manufacturers - Phenolic Red Film Faced Plywood for Construction – Xinbailin

China Wholesale Birch Plywood Board Manufacturers - Phenolic Red Film Faced Plywood for Construction – Xinbailin Detail:

Process Features

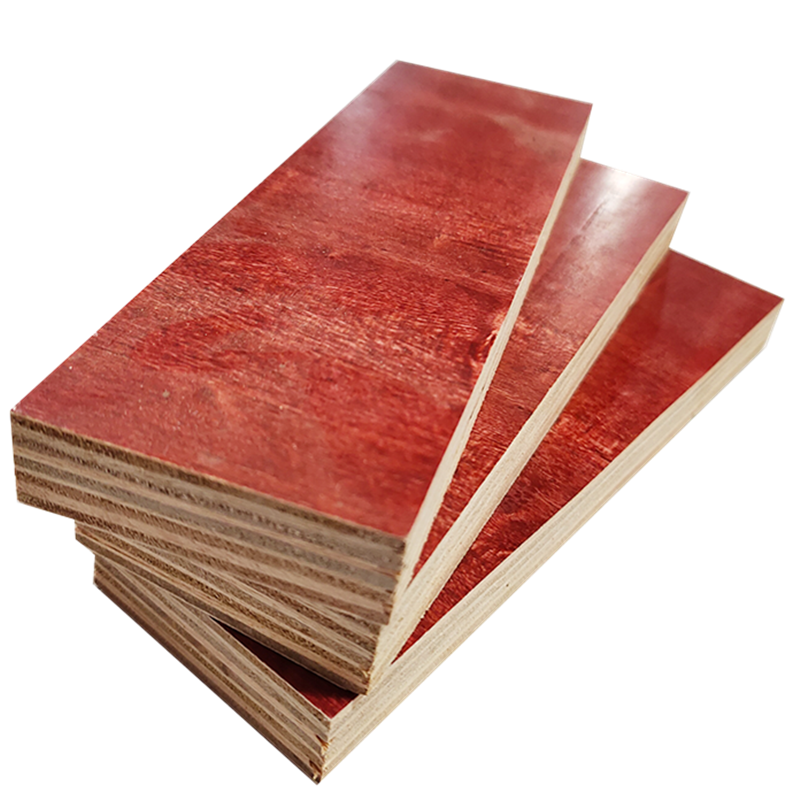

1. Use good pine and eucalyptus whole core boards, and there are no holes in the middle of the blank boards after sawing;

2. The surface coating of the construction plywood is phenolic resin glue with strong waterproof performance, and the core board adopts three ammonia glue (single-layer glue is up to 0.45KG), and layer-by-layer glue is adopted;

3. First cold-pressed and then hot-pressed, and pressed twice, the construction plywood is glued and the structure is stable.

Problems and Prevention

1. Cracks: Reasons: panel cracks, rubber board cracks. Preventive measures: When screening (when selecting boards), pay attention to pick them out, screen non-destructive plastic boards, and arrange them neatly.

2. Overlap: Reason: plastic board, dry board, the filling is too large (the interval is too large (too small). Preventive measures: fill the hole according to a certain size, and cannot exceed the original hole.

3. White leakage: Reason: It is not uniform enough when the red oil is passed once or twice. Preventive measures: During the inspection, manually add red oil.

4. Explosion board: Reason: wet board (plastic board) is not dry enough. Precautions: Inspect wood core boards when shipping.

5. The board surface is rough: Reason: fill the hole, the wood core board knife tail is thinner. Preventive measures: try to choose a flat wood core board.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | Phenolic Red Film Faced Plywood for Construction | Core | pine, eucalyptus or requested by clients |

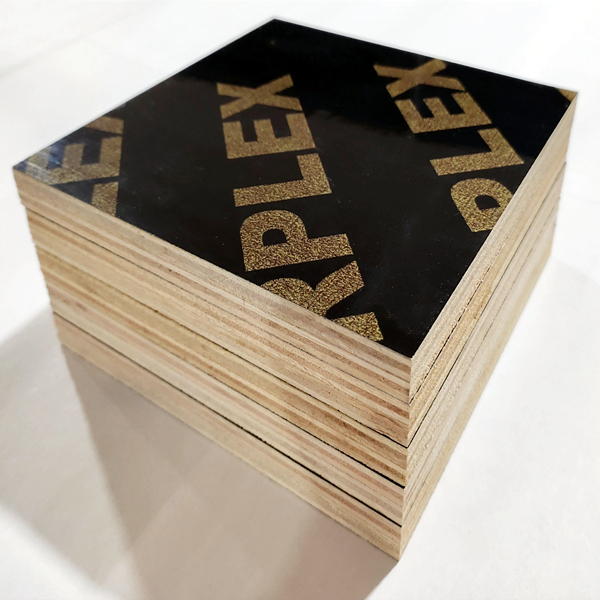

| Grade | FIRST-CLASS | Face/Back | Red glue paint(can print logo) |

| Size | 1220*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 11.5mm~18mm or as required | Moisture content | 5%-14% |

| Number of Plies | 9-10 layers | Density | 500-700kg/cbm |

| Thickness Tolerance | +/-0.3mm | Packing | Standard export packing |

| Usage | Outdoor, construction, bridge, etc. | MOQ | 1*20GP. Less is acceptable |

| Delivery Time | Within 20 days after order confirmed | Payment Terms | T/T, L/C |

Product detail pictures:

Related Product Guide:

High quality Very first,and Consumer Supreme is our guideline to offer the most beneficial service to our consumers.At present, we're attempting our greatest to be among the top exporters in our area to fulfill buyers far more need to have for China Wholesale Birch Plywood Board Manufacturers - Phenolic Red Film Faced Plywood for Construction – Xinbailin , The product will supply to all over the world, such as: US, Sudan, Roman, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!