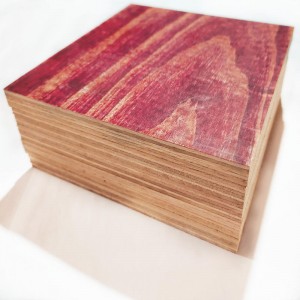

18 Mm Veneer Pine Shutter Plywood

1. Use good pine and eucalyptus whole core boards, and there are no holes in the middle of the blank boards after sawing;

2. The surface coating of the building formwork is phenolic resin glue with strong waterproof performance, and the core board adopts three ammonia glue (single-layer glue is up to 0.45KG), and layer-by-layer glue is adopted;

3. First cold-pressed and then hot-pressed, and pressed twice, the plywood is glued and the structure is stable.

1. Light weight:

It is suitable for furniture, decoration, the construction of viaduct and tall frame building

2. Large format:

The largest format is 1220*2440MM,which reduces patchworks, improving working effectiveness.

3. No warping, no distortion, no cracking, good water resistance, high turnover and long service life.

4. Low formaldehyde emission.

5. Being used to make concrete:

The film is easily to be moved, which is one of seven to steel form work. It can shorten working time.

6. Corrosion resistance:

No pollution on the surface of concrete.

7. The characteristic of film faced plywood is beneficial to construction in winter.

8.It can be made into bending template.

9.Good performance in construction:

The function in nailing, sawing and drilling is far better than bamboo plywood and steel template, It can be made into various shape's template.

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Model Number | 18 MM Veneer Pine Shurtter Plywood | Core | pine, eucalyptus or requested by clients |

| Grade | FIRST-CLASS | Face/Back | Red glue paint(can print logo) |

| Size | 1220*2440mm | Glue | MR, melamine, WBP, phenolic |

| Thickness | 11-25mm or as required | Moisture content | 5%-14% |

| Number of Plies | 9-12 layers | Density | 500-700kg/cbm |

| Thickness Tolerance | +/-0.3mm | Packing | Standard export packing |

| Usage | Outdoor, construction, bridge, etc. | MOQ | 1*20GP. Less is acceptable |

| Delivery Time | Within 20 days after order confirmed | Payment Terms | T/T, L/C |