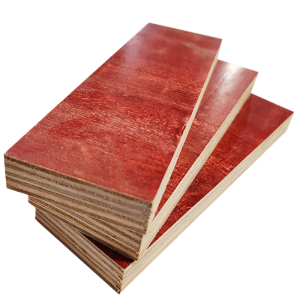

100% Original China Custom Laminated Plywood for Concrete Construction Sites

With this motto in mind, we've got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for 100% Original China Custom Laminated Plywood for Concrete Construction Sites, You would not have any communication problem with us. We sincerely welcome prospects all around the planet to call us for business enterprise cooperation.

With this motto in mind, we've got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Plastic Faced Plywood, Hardwood Plywood, We've got sufficient experience in producing solutions according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

Product Details

How to improve the selection ability of wooden plywood, please look at the following aspects:

First of all, please check whether the surface of the wooden plywood is smooth and flat: smooth and flat, making it easy to demold during use, the surface of the concrete is smooth, and it also indicates the amount of glue on the surface (the more amount of glue, the brighter and flatter the surface). Secondly, whether the assembly is uniform during the production process(unbalanced, pressed out of the board, it is not flat). Finally, whether the thickness of the board edge is the same. If the board-to-board tolerance is large, the concrete surface will not be on the same horizontal line.

Maintenance tips

1. Clean the board surface before use.

2. When unloading the mold, two workers cooperate and pry the two ends of the board at the same time, and try to let the whole board fall horizontally.

3. If there is a crack on the edge, saw it off during the cleaning process.

Why choose us

1. We provide from our own factory directly, giving a rock bottom price, so our price is more competitive.

2. All products are to be produced according to your order including samples.

3. Strict quality control. We're responsible for every batch of shipment.

4. Fast delivery and safe shipping way.

5. We will bring you quality after-sale service.

Parameter

| Place of Origin | Guangxi, China | Main Material | Pine, eucalyptus |

| Brand Name | Monster | Core | Pine, eucalyptus or requested by clients |

| Model Number | Film Faced Plywood Black Board | Face/Back | Black(faced phenolic glue) |

| Grade/Certificate | FIRST-CLASS/FSC or requested | Glue | MR, melamine, WBP, phenolic |

| Size | 1830mm*915mm/1220mm*2440mm | Moisture content | 5%-14% |

| Thickness | 11mm~21mm or as required | Density | 610-685 kg/cbm |

| Number of Plies | 8-12layers | Packing | Standard export packing |

| Usage | Outdoor, construction, road, etc. | Payment Terms | T/T, L/C |

| Delivery Time | Within 15 days after order confirmed | MOQ | 1*20GP. Less is acceptable |

With this motto in mind, we've got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for 100% Original China Waterproof Customized PP Hollow Formwork Plastic Board for Concrete Construction Site Replace Plywood, You would not have any communication problem with us. We sincerely welcome prospects all around the planet to call us for business enterprise cooperation.

100% Original China Plastic Faced Plywood, Hardwood Plywood, We've got sufficient experience in producing solutions according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.